Searching for business intelligence software companies?

|

Would you like a more agile, flexible software platform for pulling together disparate data sources for dashboards and reporting? |

|

Do you want a solution that is quick to deploy and easy to use? |

|

InetSoft offers a small-footprint, full-featured BI platform that can be deployed on commodity servers. The single Web-based application provides a streamlined, intuitive interface for all users, business executives and database analysts. |

|

As an innovator in BI products since 1996, InetSoft's award-winning software has been deployed at thousands of organizations worldwide and integrated into dozens of other application providers' solutions serving vertical and horizontal markets of their own. |

| #1 Ranking: Read how InetSoft was rated #1 for user adoption in G2's user survey-based index | Read More |

What Business Intelligence Metrics Are Tracked by Abscission Agent Production Companies?

When considering Business Intelligence (BI) metrics tracked by these companies, the focus shifts towards optimizing production, ensuring regulatory compliance, maintaining safety, and managing costs. Here are key BI metrics tracked by Abscission Agent Production companies, along with their definitions and significance in performance management:

1. Production Efficiency Metrics

a. Yield Rate

- Definition: The ratio of the amount of abscission agent produced to the raw materials used.

- Significance: High yield rates indicate efficient use of raw materials, which reduces waste and production costs.

b. Production Downtime

- Definition: The amount of time production is halted due to equipment failure, maintenance, or other issues.

- Significance: Minimizing downtime increases overall production capacity and efficiency.

2. Quality Control Metrics

a. Defect Rate

- Definition: The percentage of products that fail to meet quality standards.

- Significance: Lower defect rates suggest better quality control processes, which leads to higher customer satisfaction and reduced waste.

b. Compliance with Specifications

- Definition: The percentage of products that meet specified quality standards and regulatory requirements.

- Significance: Ensuring compliance maintains the company's reputation and avoids legal penalties.

3. Safety Metrics

a. Incident Rate

- Definition: The number of safety incidents (e.g., accidents, near-misses) per defined work hours.

- Significance: A lower incident rate indicates a safer working environment, which is crucial for employee well-being and compliance with safety regulations.

b. Lost Time Injury Frequency Rate (LTIFR)

- Definition: The number of lost time injuries per million hours worked.

- Significance: Tracking LTIFR helps assess the effectiveness of safety protocols and the need for improvements in safety measures.

4. Environmental Metrics

a. Emission Levels

- Definition: The amount of pollutants released into the environment during production.

- Significance: Keeping emissions within regulatory limits is essential for environmental compliance and reducing the company's ecological footprint.

b. Waste Generation and Disposal

- Definition: The quantity of waste produced and the methods used for its disposal.

- Significance: Effective waste management practices reduce environmental impact and enhance sustainability efforts.

5. Financial Metrics

a. Cost per Unit

- Definition: The average cost to produce one unit of the abscission agent.

- Significance: Monitoring cost per unit helps in identifying areas for cost reduction and improving overall profitability.

b. Return on Investment (ROI)

- Definition: The financial return gained from investments made in production improvements and innovations.

- Significance: High ROI indicates successful investment strategies and efficient use of capital.

6. Operational Metrics

a. Throughput

- Definition: The amount of abscission agent produced over a specific period.

- Significance: High throughput reflects the efficiency of production processes and the ability to meet market demand.

b. Inventory Turnover

- Definition: The rate at which inventory is used or sold over a given period.

- Significance: High inventory turnover indicates efficient inventory management, reducing holding costs and potential waste.

7. Supply Chain Metrics

a. Supplier Performance

- Definition: Evaluation of suppliers based on delivery time, quality of raw materials, and cost.

- Significance: Reliable suppliers ensure a steady flow of high-quality materials, crucial for maintaining consistent production quality and efficiency.

b. Lead Time

- Definition: The time taken from ordering raw materials to receiving them.

- Significance: Short lead times improve production scheduling and responsiveness to market changes.

8. Customer Satisfaction Metrics

a. Customer Complaints

- Definition: The number of complaints received regarding product quality, delivery, and performance.

- Significance: Tracking complaints helps identify and address issues promptly, improving customer satisfaction and retention.

b. Net Promoter Score (NPS)

- Definition: A measure of customer loyalty and likelihood to recommend the company's products.

- Significance: High NPS indicates strong customer satisfaction and positive brand reputation.

9. Regulatory Compliance Metrics

a. Audit Compliance Rate

- Definition: The percentage of successful regulatory audits.

- Significance: High compliance rates ensure adherence to legal standards, avoiding fines and enhancing the company's credibility.

b. Certification and Standards Compliance

- Definition: Adherence to industry certifications and standards (e.g., ISO certifications).

- Significance: Maintaining certifications demonstrates commitment to quality and regulatory compliance.

10. Innovation and Development Metrics

a. Research and Development (R&D) Spend

- Definition: The amount invested in developing new products and improving existing ones.

- Significance: R&D investment is critical for innovation, maintaining competitive advantage, and meeting evolving market needs.

b. New Product Introduction Rate

- Definition: The frequency of introducing new or improved products to the market.

- Significance: A high rate of product innovation keeps the company competitive and responsive to market demands.

What Business Intelligence Metrics Are Tracked by Abrasive Product Distribution Companies?

Abrasive product distribution companies play a crucial role in the supply chain by ensuring that manufacturers and end-users have access to necessary abrasive materials for various industrial applications. Effective business intelligence (BI) metrics are essential for optimizing operations, ensuring customer satisfaction, and maintaining financial health. Here are key BI metrics tracked by abrasive product distribution companies, along with their definitions and significance in performance management:

1. Inventory Management Metrics

a. Inventory Turnover Rate

- Definition: The number of times inventory is sold and replaced over a specific period.

- Significance: High turnover rates indicate efficient inventory management and strong sales performance, reducing holding costs and minimizing obsolescence.

b. Stock-Out Rate

- Definition: The frequency at which items are out of stock when there is customer demand.

- Significance: Low stock-out rates improve customer satisfaction by ensuring product availability and preventing lost sales.

c. Days Inventory Outstanding (DIO)

- Definition: The average number of days that inventory is held before it is sold.

- Significance: Lower DIO indicates efficient inventory management, reducing holding costs and freeing up working capital.

2. Supply Chain Efficiency Metrics

a. Order Fulfillment Cycle Time

- Definition: The total time taken from receiving a customer order to delivering the product.

- Significance: Shorter cycle times enhance customer satisfaction and competitiveness by ensuring timely delivery.

b. On-Time Delivery Rate

- Definition: The percentage of orders delivered on or before the promised delivery date.

- Significance: High on-time delivery rates improve customer trust and loyalty by meeting delivery commitments.

c. Supplier Lead Time

- Definition: The time taken by suppliers to deliver raw materials or products after an order is placed.

- Significance: Short and reliable lead times enable better inventory planning and responsiveness to market demand.

3. Financial Performance Metrics

a. Gross Profit Margin

- Definition: The difference between sales revenue and the cost of goods sold, expressed as a percentage of sales revenue.

- Significance: High gross profit margins indicate efficient cost management and pricing strategies, contributing to overall profitability.

b. Return on Assets (ROA)

- Definition: The ratio of net income to total assets, measuring how effectively a company uses its assets to generate profit.

- Significance: High ROA reflects efficient use of assets and effective management practices.

c. Operating Expenses Ratio

- Definition: The ratio of operating expenses to total revenue.

- Significance: Lower operating expenses ratios indicate better control over costs, enhancing profitability.

4. Sales and Marketing Metrics

a. Sales Growth Rate

- Definition: The percentage increase in sales revenue over a specific period.

- Significance: Positive sales growth indicates successful marketing strategies and market demand for the products.

b. Customer Acquisition Cost (CAC)

- Definition: The total cost of acquiring a new customer, including marketing and sales expenses.

- Significance: Lower CAC indicates more efficient customer acquisition processes, improving overall profitability.

c. Customer Lifetime Value (CLV)

- Definition: The total revenue a company expects to earn from a customer over the duration of their relationship.

- Significance: High CLV suggests strong customer retention and the effectiveness of customer relationship management strategies.

5. Customer Service Metrics

a. Net Promoter Score (NPS)

- Definition: A measure of customer satisfaction and loyalty, based on the likelihood of customers recommending the company to others.

- Significance: High NPS indicates strong customer satisfaction and positive brand reputation.

b. Customer Satisfaction Score (CSAT)

- Definition: A measure of customer satisfaction with a specific product or service.

- Significance: High CSAT scores reflect successful fulfillment of customer expectations and needs.

c. First Contact Resolution (FCR)

- Definition: The percentage of customer issues resolved on the first contact with customer support.

- Significance: High FCR rates improve customer satisfaction by providing efficient and effective support.

6. Operational Efficiency Metrics

a. Order Accuracy Rate

- Definition: The percentage of orders fulfilled without errors.

- Significance: High order accuracy rates reduce returns and improve customer satisfaction.

b. Warehouse Utilization Rate

- Definition: The percentage of warehouse space effectively used for storing inventory.

- Significance: High utilization rates indicate efficient use of warehouse space, reducing overhead costs.

c. Picking and Packing Efficiency

- Definition: The speed and accuracy of the picking and packing process in the warehouse.

- Significance: Efficient picking and packing operations enhance order fulfillment speed and accuracy, reducing labor costs and improving customer satisfaction.

7. Regulatory Compliance Metrics

a. Compliance Rate

- Definition: The percentage of operations and processes that comply with industry regulations and standards.

- Significance: High compliance rates avoid legal penalties and enhance the company's reputation for reliability and responsibility.

b. Audit Success Rate

- Definition: The percentage of successful audits passed without significant issues.

- Significance: A high audit success rate indicates robust internal controls and adherence to regulatory requirements.

8. Innovation and Development Metrics

a. Research and Development (R&D) Investment

- Definition: The amount invested in developing new products or improving existing ones.

- Significance: Sustained R&D investment fosters innovation, keeping the company competitive and responsive to market needs.

b. New Product Introduction Rate

- Definition: The frequency of launching new or improved products in the market.

- Significance: A high introduction rate suggests a proactive approach to meeting customer demands and staying ahead of competitors.

|

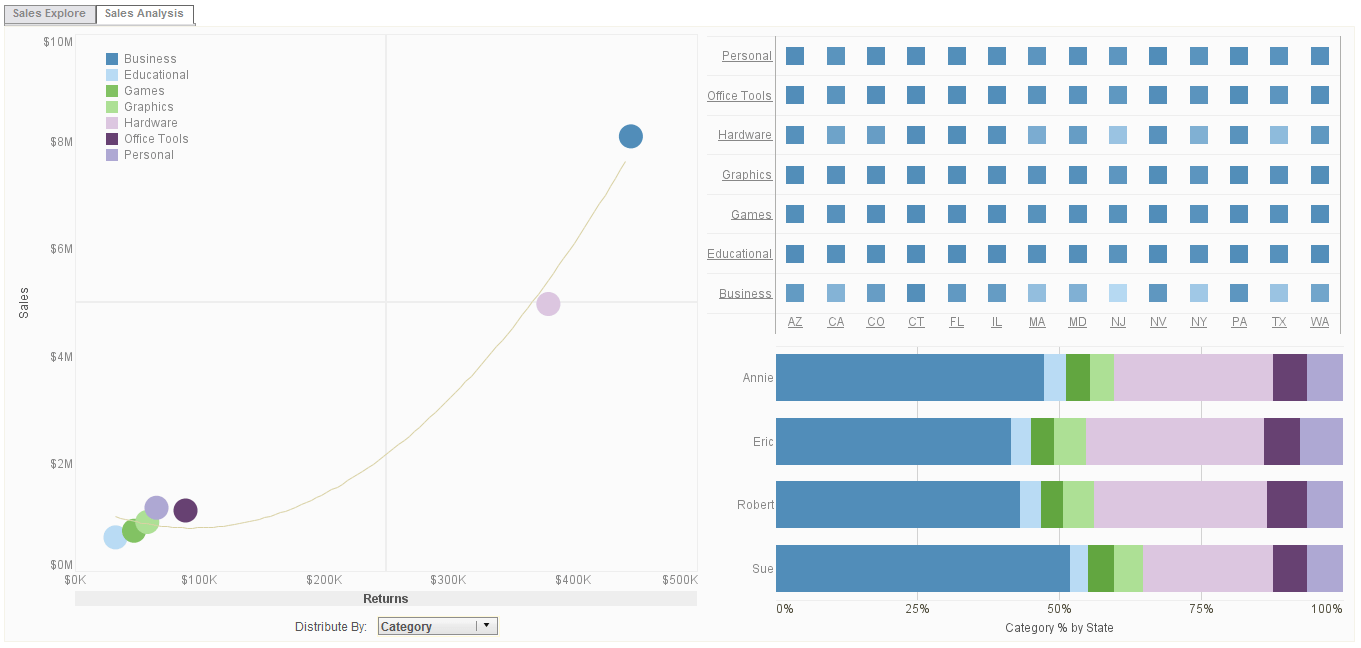

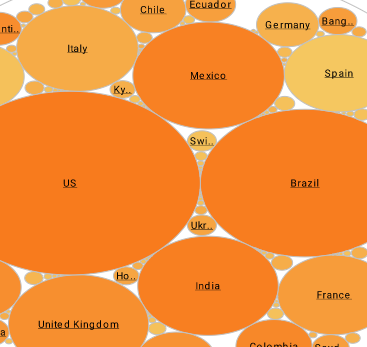

View live interactive examples in InetSoft's dashboard and visualization gallery. |

What Products and Materials Do Abrasive Product Distribution Companies Sell?

Abrasive product distribution companies provide a wide range of products and materials that cater to various industries, including manufacturing, automotive, construction, and metalworking. These products are essential for tasks such as grinding, cutting, polishing, and surface preparation. Here is a detailed list of the types of products and materials that abrasive product distribution companies typically sell:

1. Abrasive Grains and Powders

- Aluminum Oxide: Widely used for its toughness and strength, suitable for grinding metals and wood.

- Silicon Carbide: Harder than aluminum oxide, ideal for cutting and grinding harder materials like stone, glass, and ceramics.

- Ceramic Abrasives: High-performance abrasives known for durability and efficiency, often used in high-pressure applications.

- Garnet: Natural abrasive used for waterjet cutting and sandblasting, preferred for its recyclability and minimal environmental impact.

2. Bonded Abrasives

- Grinding Wheels: Used for precision grinding and finishing of metals and other materials. Available in various shapes and sizes.

- Cut-off Wheels: Thin wheels used for cutting metal and other hard materials.

- Mounted Points: Small grinding tools used for detailed work in hard-to-reach areas.

3. Coated Abrasives

- Sandpaper and Sanding Discs: Sheets and discs coated with abrasive grains, used for smoothing surfaces.

- Abrasive Belts: Used in belt sanders for continuous grinding or sanding applications.

- Abrasive Rolls: Rolls of coated abrasive material that can be cut to size for various applications.

4. Non-Woven Abrasives

- Abrasive Pads and Hand Pads: Used for light cleaning, blending, and finishing.

- Surface Conditioning Discs: Discs made of non-woven material, used for surface preparation and finishing.

5. Abrasive Blasting Media

- Glass Beads: Used for peening and cleaning surfaces without damaging the material.

- Steel Shot and Grit: Heavy-duty media for cleaning and surface preparation of metals.

- Plastic Media: Used for delicate applications, such as cleaning aerospace components without damaging surfaces.

- Walnut Shells and Corn Cob: Organic media used for gentle cleaning and polishing applications.

6. Diamond Abrasives

- Diamond Blades: Used for cutting hard materials like concrete, stone, and glass.

- Diamond Grinding Wheels: Used for precision grinding and finishing of hard materials.

- Diamond Paste: Used for polishing and finishing applications where high precision is required.

7. Superabrasives

- Cubic Boron Nitride (CBN) Wheels: Used for grinding ferrous materials due to their high thermal stability and hardness.

- Polycrystalline Diamond (PCD) Tools: Used in cutting and machining applications for hard and abrasive materials.

8. Abrasive Brushes

- Wire Brushes: Used for cleaning, deburring, and surface preparation.

- Nylon Abrasive Brushes: Contain abrasive grains within the nylon filaments, used for cleaning and finishing applications.

9. Polishing Compounds and Pads

- Polishing Pads: Used in conjunction with polishing compounds to achieve a high-gloss finish on various surfaces.

- Polishing Compounds: Abrasive pastes or liquids used to achieve a fine finish and high shine.

10. Specialty Abrasives

- Flap Discs and Flap Wheels: Combine the benefits of both grinding and finishing in one tool, used for weld blending, deburring, and rust removal.

- Quick-Change Discs: Small discs that attach quickly to tools for easy and fast abrasive changes.

- Abrasive Sponges: Flexible sponges coated with abrasive material, used for detailed sanding and finishing.

11. Abrasive Tools and Accessories

- Backing Pads: Used to support sanding discs during use.

- Mandrels and Adapters: Attachments used to secure abrasive products to power tools.

- Abrasive Drums: Used for sanding and finishing in cylindrical forms, often used with spindle sanders.

12. Safety and Personal Protective Equipment (PPE)

- Dust Masks and Respirators: Protect workers from inhaling harmful dust and particles during abrasive operations.

- Safety Glasses and Face Shields: Provide eye protection from flying debris.

- Gloves: Protect hands from abrasions and chemicals.

|

Read how InetSoft saves money and resources with deployment flexibility. |

More Articles About Companies Using BI

Evaluate InetSoft's Big Data Dashboard Tool - Are you looking for good big data dashboard tools? InetSoft's pioneering dashboard reporting application makes producing great-looking web-based reports and dashboards easy with a drag-and-drop designer and the ability to connect to all types of big data sources. View a demo and try interactive examples...

Free Reporting Tools for Excel Data - There are three free reporting tools for Excel data to suggest. All of them are cloud-based, meaning there is no software to download. 1. The first is Visualize Free. Register any address. Upload your spreadsheet from any Microsoft version and use the drag and drop designer to create interactive and paginated reports. It is best for ad hoc or one-time report projects...

How Is InetSoft's Data Presentation Software So Easy to Use? - Data presentation is the means by which more and more organizations are answering key questions about their businesses. Data presentation consists not so much of presenting raw data, but of information, such as complex numbers and statistics, in a clear and beautiful way through mediums such as bar and line graphs, or pie charts...

Tools Used by Data Analysts - To understand the capability of and utilize the wide range of software and tools available in the market, this page will discuss the most important and well-known tools that one may need to carry out data analysis professionally. These tools are effective in simplifying complex analytic tasks, thus making the professional analyst's work easier. With these tools, the analysts can spend more time understanding the outcomes of the analysis process rather than carrying out the analysis. So here are the different types of data analyst tools...