Evaluate InetSoft's BI Tool

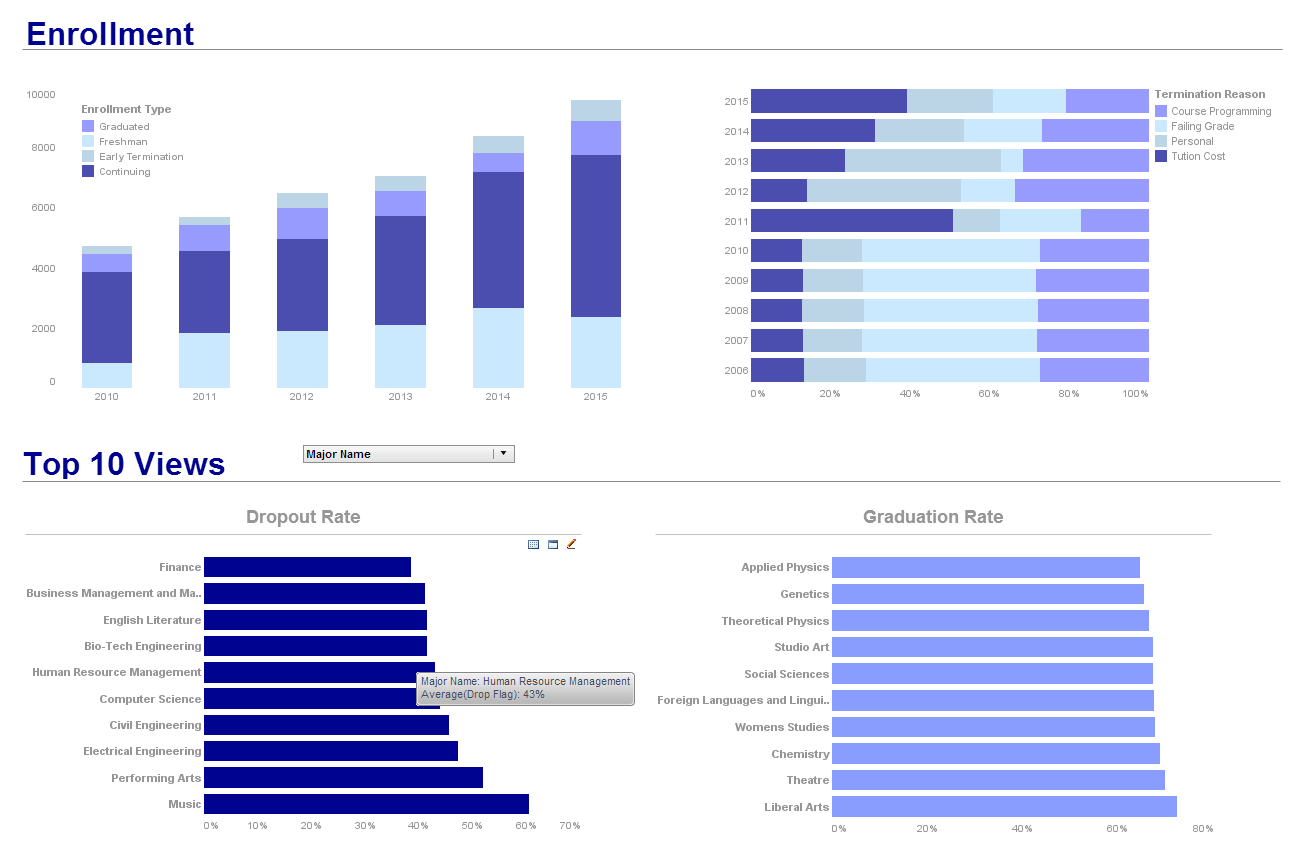

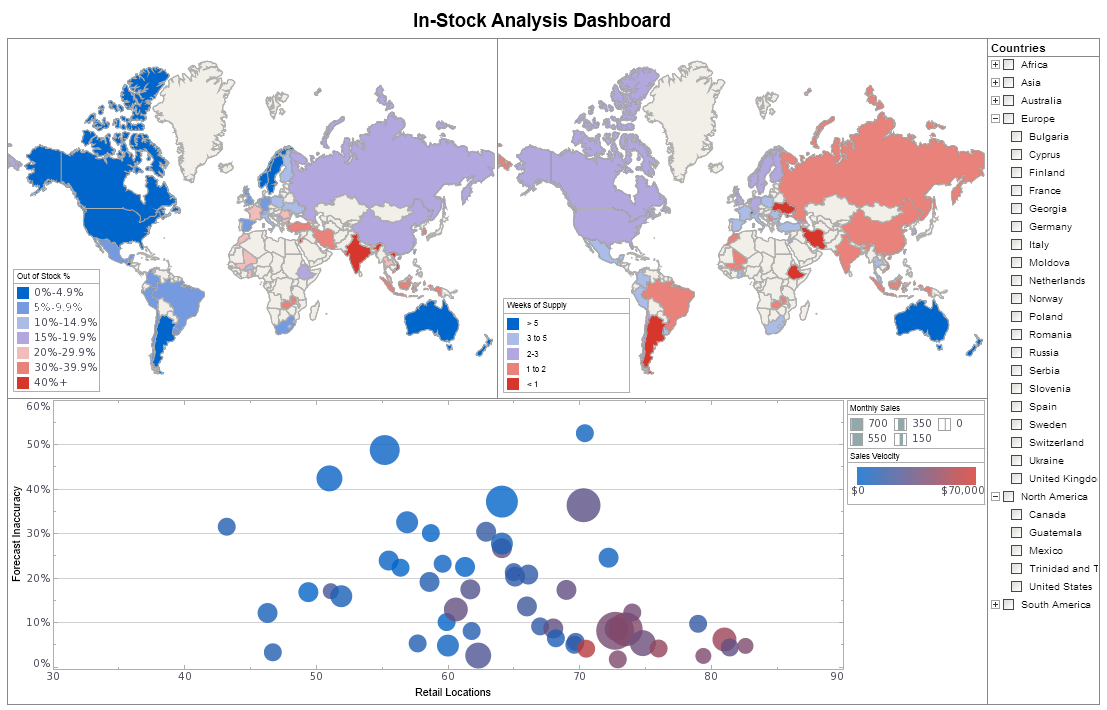

Are you looking to evaluate BI tools? Since 1996 InetSoft has been making BI software that is easy to deploy and easy to use. Build self-service oriented dashboards and visual analyses quickly. InetSoft's data mashup engine solves the data access and transformation challenges that other tools cannot. View a demo and download one of our applications for free.

Why InetSoft?

InetSoft's web based BI tool is easy enough to be:- Deployed in just weeks

- Learned by end users with minimal training

- Used by any executive without the aid of IT

- Adaptable to changing data and business needs

- Used for data exploration through visualization

- Capable of maximum self-service

- Attract the attention of executives

- Meet the demands of power users

- Scale up for organizations of any size

Evaluate Style Scope from InetSoft. It's Easy. Agile. & Robust.

Register for more info and free software software

About InetSoft

Since 1996 InetSoft has been delivering easy, agile, and robust business intelligence software that makes it possible for organizations and solution providers of all sizes to deploy or embed full-featured business intelligence solutions. Application highlights include visually-compelling and interactive dashboards that ensure greater end-user adoption plus pixel-perfect report generation, scheduling, and bursting. InetSoft's patent pending Data Block™ technology enables productive reuse of queries and a unique capability for end-user defined data mashup.

This capability combined with efficient information access enabled by InetSoft's visual analysis technologies allows maximum self-service that benefits the average business user, the IT administrator, and the developer. InetSoft was rated #1 in Butler Analytics Business Analytics Yearbook, and InetSoft's BI solutions have been deployed at over 5,000 organizations worldwide, including 25% of Fortune 500 companies, spanning all types of industries.

What KPIs and Metrics Do Operators of Wind Farms Track with BI Tools?

Operators of wind farms utilize Business Intelligence (BI) tools to track various key performance indicators (KPIs) and metrics to monitor and optimize the performance of their wind turbines and overall operations. Here are some common KPIs and their definitions, along with their significance in performance management:

-

Capacity Factor: Capacity factor measures the actual energy output of a wind turbine or wind farm relative to its maximum potential output over a specific period, usually expressed as a percentage. A higher capacity factor indicates better utilization of available wind resources and higher efficiency in generating electricity.

-

Availability: Availability measures the percentage of time that a wind turbine or wind farm is operational and able to generate electricity. It accounts for downtime due to maintenance, repairs, and other factors. Maximizing availability ensures consistent energy production and revenue generation.

-

Performance Ratio: Performance ratio (PR) compares the actual energy output of a wind turbine or wind farm to its theoretical maximum output under ideal conditions, considering factors such as wind speed and turbine efficiency. It helps evaluate the overall performance and efficiency of the equipment.

-

Downtime: Downtime refers to the period during which a wind turbine or wind farm is not operational due to unplanned maintenance, repairs, or other issues. Minimizing downtime is crucial for maximizing energy production and revenue.

-

Production Losses: Production losses encompass various factors that contribute to reduced energy output, such as equipment failures, suboptimal operating conditions, and curtailment due to grid constraints. Identifying and mitigating production losses is essential for optimizing performance and profitability.

-

Wind Speed and Direction: Wind speed and direction data are critical for assessing the availability of wind resources and optimizing the operation of wind turbines. Monitoring variations in wind patterns helps operators adjust turbine settings and maximize energy capture.

-

Revenue and Cost Metrics: Operators track revenue generated from energy sales as well as operational costs, including maintenance, repairs, and personnel expenses. Analyzing revenue and cost metrics enables informed decision-making to improve profitability and financial performance.

-

Environmental Performance: Environmental performance metrics may include carbon emissions reductions, wildlife impact assessments, and compliance with regulatory standards for environmental stewardship. Monitoring environmental performance helps ensure sustainable operations and adherence to regulatory requirements.

-

Turbine Health and Maintenance Status: BI tools can track data related to turbine health, including vibration levels, temperature, and oil condition, to assess equipment condition and schedule proactive maintenance activities. Maintaining turbine health is essential for minimizing downtime and maximizing longevity.

-

Energy Forecast Accuracy: Energy forecast accuracy measures the precision of predictions regarding future energy production based on weather forecasts and historical data. Improving forecast accuracy enhances operational planning and resource allocation, leading to optimized energy production and grid integration.

How Is Artificial Intelligence Used the Wind Farming Industry?

Artificial Intelligence (AI) is increasingly being employed in the wind farming industry to enhance operational efficiency, optimize energy production, and improve maintenance practices. Here are several ways AI is used in the wind farming industry:

-

Predictive Maintenance: AI algorithms analyze sensor data from wind turbines to predict potential equipment failures before they occur. By detecting anomalies and patterns in data related to temperature, vibration, and other parameters, AI systems can anticipate maintenance needs and schedule repairs proactively, minimizing downtime and reducing maintenance costs.

-

Performance Optimization: AI-powered optimization algorithms adjust turbine settings in real time based on factors such as wind speed, direction, and atmospheric conditions to maximize energy capture and overall performance. These algorithms continuously learn from operational data to fine-tune control strategies and improve energy efficiency.

-

Turbine Health Monitoring: AI systems monitor the health of individual wind turbines by analyzing sensor data and identifying signs of degradation or wear. By detecting early indicators of potential issues, such as component failures or structural damage, AI helps operators prioritize maintenance activities and prevent costly downtime.

-

Wind Resource Assessment: AI algorithms analyze historical weather data and wind patterns to forecast future wind conditions with greater accuracy. By predicting fluctuations in wind speed and direction, AI enables more precise energy production forecasts and assists in strategic planning for wind farm development and expansion.

-

Grid Integration and Energy Forecasting: AI-based energy forecasting models incorporate diverse data sources, including weather forecasts, grid demand patterns, and historical energy production data, to predict future energy output from wind farms. These forecasts help grid operators manage grid stability, optimize energy dispatch, and integrate renewable energy sources effectively.

-

Fault Detection and Diagnostics: AI algorithms analyze operational data from wind turbines to detect and diagnose faults or performance deviations in real time. By identifying issues such as blade damage, gearbox malfunctions, or electrical faults, AI systems enable prompt intervention and troubleshooting to minimize downtime and ensure operational reliability.

-

Automated Inspection and Monitoring: AI-powered drones equipped with cameras and sensors conduct automated inspections of wind turbine blades, towers, and other components. Machine learning algorithms analyze visual data to detect defects, cracks, or signs of wear, enabling early intervention and preventive maintenance.

-

Optimized Wind Farm Layout Design: AI algorithms optimize the layout and configuration of wind farms to maximize energy production while minimizing wake effects and turbulence between turbines. By simulating airflow patterns and conducting virtual wind farm modeling, AI assists in designing more efficient and cost-effective layouts.

-

Energy Market Analysis and Trading: AI algorithms analyze market data, including energy prices, demand forecasts, and regulatory policies, to optimize energy trading strategies and maximize revenue from wind farm operations. By identifying opportunities for arbitrage and risk mitigation, AI enhances financial performance and market competitiveness.