Researching performance management solutions for your organization's internal use or to embed in a commercial application?

|

Deploy a small-footprint, easy-to-use web-based performance reporting application from InetSoft. |

|

As an innovator in reporting software since 1996, InetSoft has pioneered the evolution from static reporting towards interactive visualization of data to monitor business performance. |

|

InetSoft's award-winning software has been deployed at thousands of organizations worldwide and integrated into dozens of other application providers' solutions serving vertical and horizontal markets of their own. |

|

Try a free evaluation copy of StyleBI, InetSoft's all-inclusive business intelligence software platform that includes the reporting application, Style Report Enterprise, and the dashboard application, Style Scope. |

Why InetSoft?

InetSoft's mobile BI reporting application is easy enough to be:

- Deployed in just weeks

- Learned by end users with minimal training

- Used by any executive without the aid of IT

agile enough to be:

- Adaptable to changing data and business needs

- Used for data exploration through visualization

- Capable of maximum self-service

and robust enough to:

- Attract the attention of executives

- Meet the demands of power users

- Scale up for organizations of any size

Evaluate StyleBI from InetSoft. It's Easy. Agile. & Robust.

Register for more info and to download free eval software

About InetSoft

Since 1996 InetSoft has been delivering easy, agile, and robust business intelligence software that makes it possible for organizations and solution providers of all sizes to deploy or embed full-featured business intelligence solutions. Application highlights include visually-compelling and interactive dashboards that ensure greater end-user adoption plus pixel-perfect report generation, scheduling, and bursting. InetSoft's patent pending Data Block™ technology enables productive reuse of queries and a unique capability for end-user defined data mashup.

This capability combined with efficient information access enabled by InetSoft's visual analysis technologies allows maximum self-service that benefits the average business user, the IT administrator, and the developer. InetSoft was rated #1 in Butler Analytics Business Analytics Yearbook, and InetSoft's BI solutions have been deployed at over 5,000 organizations worldwide, including 25% of Fortune 500 companies, spanning all types of industries.

What KPIs and Metrics Are Tracked by Naval Ship Builders for Performance Management?

Naval shipbuilding is a highly complex and technical industry where the precision of operations and adherence to timelines are critical. Key Performance Indicators (KPIs) and metrics are essential tools used by naval shipbuilders to monitor and manage their performance effectively. These KPIs are tracked in dashboards that provide real-time insights and help in making informed decisions. Here's an in-depth look at the key KPIs, their definitions, and their significance in performance management for naval shipbuilders.

1. Project Schedule Adherence

Definition: This KPI measures the percentage of tasks completed on time against the planned schedule. It compares actual progress with the project timeline.

Significance: Adherence to the project schedule is crucial in naval shipbuilding due to the extensive timelines and complex interdependencies. Delays can lead to increased costs and can impact national security strategies. Monitoring schedule adherence helps ensure that all activities are progressing as planned and identifies any delays early so corrective actions can be taken.

2. Budget Variance

Definition: Budget variance measures the difference between the budgeted cost and the actual cost of the project. It is expressed in monetary terms or as a percentage.

Significance: Keeping projects within budget is a fundamental aspect of financial management in shipbuilding. A positive variance indicates that the project is under budget, while a negative variance signals overspending. This KPI helps in identifying cost overruns early and allows for financial adjustments to avoid project derailment.

3. Quality Control Metrics

Definition: These metrics include defect rates, rework levels, and compliance with quality standards. They measure the quality of workmanship and materials used in shipbuilding.

Significance: Quality control is vital in ensuring that the ships meet rigorous standards for safety, performance, and durability. High defect rates or significant rework can lead to delays and increased costs. Monitoring quality control metrics helps maintain high standards and ensures that the end product is reliable and fit for purpose.

4. Safety Incident Rate

Definition: This KPI tracks the number of safety incidents, including accidents and near-misses, per 100,000 hours worked.

Significance: Shipbuilding is a hazardous industry, and maintaining a safe working environment is paramount. A high safety incident rate can lead to lost time, increased insurance costs, and a negative impact on workforce morale. Tracking safety incidents helps identify potential hazards and implement measures to prevent future occurrences.

5. Resource Utilization

Definition: Resource utilization measures how effectively the workforce, machinery, and materials are used during the shipbuilding process. It is often expressed as a percentage.

Significance: Optimal resource utilization ensures that all resources are being used efficiently, which can lead to cost savings and improved productivity. Over or underutilization can indicate inefficiencies that need to be addressed. This KPI helps in balancing workloads and improving operational efficiency.

6. Supply Chain Performance

Definition: This metric tracks the reliability and efficiency of the supply chain, including on-time delivery of materials, inventory levels, and supplier performance.

Significance: The supply chain is critical in naval shipbuilding, where delays or shortages in materials can halt production. Efficient supply chain performance ensures that materials are available when needed, reducing downtime and keeping the project on track. It also helps in building strong relationships with reliable suppliers.

7. Workforce Productivity

Definition: Workforce productivity measures the output of the workforce in terms of completed tasks or milestones within a specific timeframe.

Significance: High productivity indicates that the workforce is operating efficiently and meeting production targets. Low productivity can signal issues such as insufficient training, low morale, or inadequate planning. This KPI helps in identifying areas where workforce performance can be improved through training, motivation, or better resource allocation.

8. Customer Satisfaction

Definition: Customer satisfaction measures the client's satisfaction with the project progress, quality, and adherence to specifications. It is usually gathered through surveys or feedback forms.

Significance: In naval shipbuilding, the primary customer is often a government or military body, and their satisfaction is crucial for future contracts and ongoing relationships. High customer satisfaction indicates that the project meets or exceeds expectations, while low satisfaction can jeopardize future business. This KPI helps in ensuring that customer requirements are understood and met.

9. Cycle Time

Definition: Cycle time measures the time taken to complete a specific phase of the shipbuilding process or the entire project.

Significance: Reducing cycle time without compromising quality can lead to faster delivery of ships, giving naval forces the capabilities they need sooner. Long cycle times can indicate inefficiencies and bottlenecks in the process. Monitoring cycle time helps in identifying areas for process improvement and faster project completion.

10. Earned Value Management (EVM)

Definition: EVM is a comprehensive project management metric that combines scope, schedule, and cost performance. It includes metrics like Cost Performance Index (CPI) and Schedule Performance Index (SPI).

Significance: EVM provides a holistic view of project performance and progress. CPI indicates cost efficiency, while SPI shows schedule efficiency. This KPI helps project managers understand whether the project is on track financially and temporally, enabling better decision-making and corrective actions.

11. Risk Management Metrics

Definition: These metrics track identified risks, their potential impact, and the effectiveness of mitigation strategies. They often include risk severity and risk occurrence rates.

Significance: Effective risk management is crucial in shipbuilding due to the high stakes involved. Tracking these metrics helps in proactively managing risks, minimizing their impact, and ensuring project continuity. It also fosters a culture of risk awareness and preparedness.

12. Environmental Impact

Definition: This KPI measures the environmental footprint of the shipbuilding process, including emissions, waste generation, and resource consumption.

Significance: With increasing focus on sustainability, minimizing the environmental impact is important for compliance and corporate responsibility. Tracking this KPI helps in implementing eco-friendly practices and reducing the environmental footprint of shipbuilding activities.

Significance in Performance Management

These KPIs and metrics are significant for several reasons:

- Enhanced Decision-Making: Real-time data from dashboards enable informed decision-making, helping managers address issues promptly.

- Improved Efficiency: Monitoring KPIs helps identify inefficiencies and bottlenecks, allowing for process improvements and better resource utilization.

- Risk Mitigation: Early identification of potential risks through KPIs helps in implementing mitigation strategies, reducing the likelihood of project disruptions.

- Financial Control: Tracking budget variance and cost performance ensures that projects remain financially viable, preventing cost overruns.

- Quality Assurance: Ensuring high-quality standards through quality control metrics helps in delivering reliable and durable ships.

- Stakeholder Satisfaction: Meeting schedule, budget, and quality expectations leads to higher customer satisfaction, fostering long-term relationships and future contracts.

- Safety and Compliance: Monitoring safety and environmental impact ensures compliance with regulations and promotes a safe working environment.

|

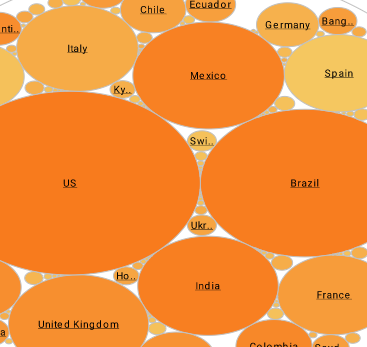

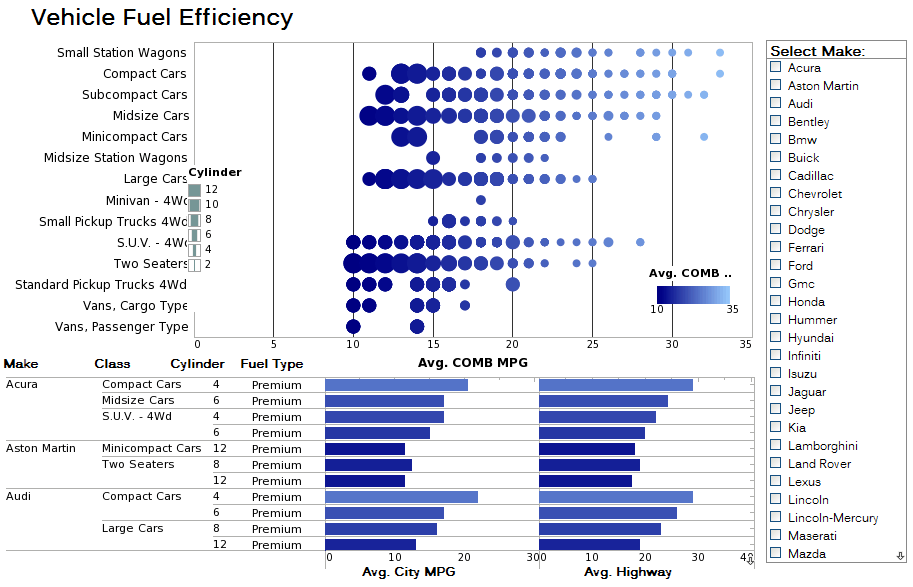

View the gallery of examples of dashboards and visualizations. |

More Articles About Performance Management

Beef Cattle Ranching KPIs - In beef cattle ranching, tracking specific Key Performance Indicators (KPIs) and metrics is essential for optimizing operations, improving productivity, and ensuring profitability. Here are some key KPIs and their definitions, along with their significance in performance management...

BI Software Testing Methods - The most granular level of software testing, unit testing, focuses on individual parts or units of code. Developers create test cases to verify the accuracy of small pieces of code independently. These tests guarantee that each component operates as expected in finding issues early in the development cycle. Test-Driven Development (TDD), in which tests are developed before the real code, is not complete without unit testing...

Customized Dashboards for Quickbooks - Custom dashboards using rich QuickBooks data lets executives focus on what's important and scale up right now. The Bison System quickly and accurately consolidates QuickBooks data. CFO's can not only create dashboards and reports, but also filter, sort, format, and organize them, bringing previously unreachable levels of analytics and interactivity to QuickBooks data...

Environment for Dashboard Development - Well, essentially StyleBI has three modes of use. There's dashboard development environment which can be used by developers, but business users actually find that quite usable too. And there's a server environment which is where IT can manage the application, the sharing and permission aspects, and where applications can be saved on the server, and be continuously used and refreshed with larger volumes of data. And then there's the device experience which spans desktops, laptops...