Looking for a Free Trial for Big Data Software?

Have you been feeling limited regarding what can be done with your Big Data sources? Have you wondered about ways of combining data from your Big Data sources with other data sources?

InetSoft allows users to download a free 5-day trial copy of StyleBI, a complete BI solution that is compatible with Big Data Sources such as Cloudera, Hadoop, MapR, and SAP HANA.

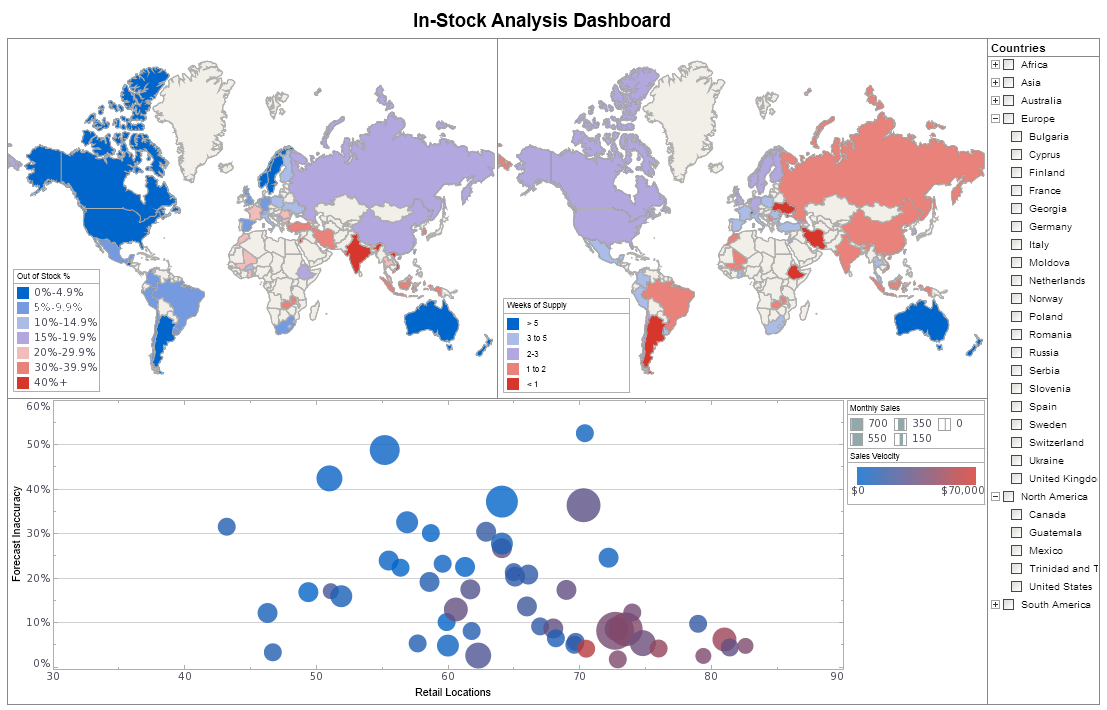

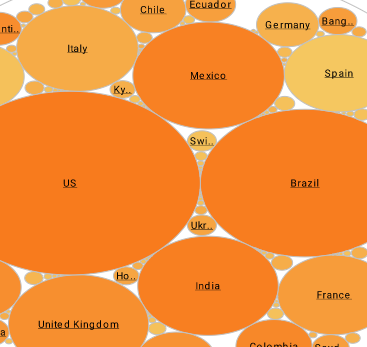

The free trial comes complete a user-friendly viewsheet that can be used to create eye-popping dashboards and visualizations with your Big Data sources. InetSoft's robust data mashup engine can mashup your Big Data with virtually any other data source, bringing actionable information into a single view.

InetSoft's data grid caching technology combines the best aspects of in-memory database reporting with disk access, enabling you to perform analytics on Big Data sources at the speed of thought.

System Requirements for Trial Download

- 200MB disk space and 1GB RAM

- Any relational database with a JDBC driver, such as Microsoft Access, MySQL, Oracle, etc.; or Microsoft Excel spreadsheets, Comma-delimited text files, and custom Web services

- Knowledge about database administration

- Web server running on destination machine

A time-limited key will be sent to you based on your evaluation timeline needs. For an extended evaluation, free technical assistance, or if you are only interested in Style Scope or Style Report, contact us.

How Does the Apparel Manufacturing Industry Use Big Data?

The apparel manufacturing industry has increasingly embraced big data to enhance various aspects of their operations. Here's a detailed look at how they leverage big data:

-

Demand Forecasting

- Big data analytics helps apparel manufacturers analyze historical sales data, social media trends, and other relevant factors to predict future demand for specific products.

- This enables them to optimize production schedules, reduce overstocking or understocking, and improve inventory management.

-

Market Trend Analysis

- By monitoring social media, fashion blogs, and e-commerce platforms, apparel manufacturers can identify emerging fashion trends and consumer preferences.

- This information guides the design process and helps in producing styles that are in high demand.

-

Personalized Product Recommendations

- Through data analytics, manufacturers can gather insights on individual customer preferences and behaviors. This allows for the creation of personalized product recommendations and targeted marketing campaigns.

-

Supply Chain Optimization

- Big data helps in optimizing the supply chain by providing real-time visibility into inventory levels, production schedules, and logistics.

- Manufacturers can use predictive analytics to anticipate potential disruptions and make adjustments to ensure timely delivery.

-

Quality Control and Assurance

- Sensors and IoT devices can be used to monitor the production process in real-time. Data from these devices helps in identifying and addressing quality issues promptly.

- Machine learning algorithms can also be employed to detect patterns associated with product defects.

-

Sustainability and Environmental Impact

- Big data allows manufacturers to track and analyze their environmental footprint. This includes monitoring energy consumption, water usage, and waste generation.

- By identifying areas for improvement, manufacturers can implement sustainable practices and reduce their environmental impact.

-

Customer Feedback and Sentiment Analysis

- Social media listening tools and sentiment analysis algorithms can be used to gather feedback from customers about specific products or brand perceptions.

- This information helps manufacturers understand customer sentiment and make necessary adjustments to products or marketing strategies.

-

Price Optimization

- Big data analytics enables manufacturers to analyze market conditions, competitor pricing, and consumer behavior to set optimal pricing strategies.

- This ensures that products are competitively priced while still maintaining profitability.

-

Production Planning and Resource Allocation

- Manufacturers can use big data to optimize production schedules based on factors like machine availability, labor capacity, and material availability.

- This helps in minimizing production bottlenecks and maximizing resource utilization.

-

Fraud Detection and Prevention

- For e-commerce and direct-to-consumer sales, big data analytics can be used to detect and prevent fraudulent activities, such as payment fraud or fake product returns.

-

Predictive Maintenance

- IoT sensors on manufacturing equipment can collect data on machine performance. Using predictive analytics, manufacturers can anticipate maintenance needs, reducing unexpected downtime and repair costs.

-

Competitive Analysis

- Big data allows manufacturers to monitor the activities of competitors, including product releases, pricing strategies, and marketing campaigns. This information helps in making informed decisions to stay competitive in the market.

|

Read how InetSoft was rated as a top BI vendor in G2 Crowd's user survey-based index. |

How Does the Chemical Manufacturing Industry Use Big Data?

The chemical manufacturing industry leverages big data in various ways to improve processes, enhance safety, and drive innovation. Here's an in-depth exploration of how they utilize big data:

-

Process Optimization

- Chemical manufacturers use big data analytics to monitor and optimize the chemical production process. This involves analyzing real-time data from sensors and IoT devices to ensure that the production process operates at maximum efficiency.

- Data-driven insights can help in adjusting variables like temperature, pressure, and chemical composition to achieve desired outcomes.

-

Quality Control and Assurance

- Big data technologies allow for the continuous monitoring of product quality. Sensors and automated systems collect data throughout the production process, enabling manufacturers to detect deviations from quality standards in real-time.

- Statistical process control (SPC) techniques can be applied to ensure consistent product quality.

-

Predictive Maintenance

- Chemical plants have a multitude of complex equipment. Big data analytics, combined with IoT sensors, are used to monitor the condition of machinery. By analyzing this data, manufacturers can predict when maintenance is needed, reducing unplanned downtime and costly repairs.

-

Supply Chain Optimization

- Big data helps in optimizing the supply chain by providing visibility into the movement of raw materials, intermediate products, and finished goods.

- Manufacturers can use predictive analytics to anticipate demand fluctuations, enabling them to adjust production schedules and inventory levels accordingly.

-

Environmental and Safety Compliance

- Compliance with environmental regulations is critical in the chemical industry. Big data analytics allow companies to monitor emissions, waste disposal, and other environmental factors to ensure adherence to regulatory standards.

- Real-time data analysis helps in identifying and addressing potential safety hazards.

-

Energy Efficiency

- Chemical manufacturing is energy-intensive. Big data analytics can be used to monitor energy consumption patterns and identify opportunities for optimization.

- By analyzing data related to energy usage, manufacturers can implement energy-saving measures and reduce operational costs.

-

Research and Development (R&D)

- Big data plays a significant role in chemical R&D. It helps in the analysis of chemical structures, properties, and interactions, accelerating the discovery and development of new compounds and materials.

- Computational modeling and simulation based on big data enable virtual testing of various formulations.

-

Market Intelligence and Demand Forecasting

- Chemical manufacturers analyze market trends, customer preferences, and competitor activities using big data. This information guides product development and marketing strategies.

- Predictive analytics aids in forecasting demand for specific chemical products, allowing manufacturers to adjust production schedules and inventory levels accordingly.

-

Risk Management

- Big data analytics are employed to assess and mitigate risks associated with chemical production. This includes identifying potential hazards, evaluating safety protocols, and developing contingency plans.

- Data-driven risk assessments help in maintaining a safe working environment.

-

Customized Product Formulation

- Big data analytics enable chemical manufacturers to create customized formulations based on specific customer requirements. This personalization enhances customer satisfaction and loyalty.

-

Regulatory Compliance and Reporting

- Big data systems assist in generating and maintaining accurate records for compliance reporting. This ensures that manufacturers adhere to legal and regulatory requirements.

|

View live interactive examples in InetSoft's dashboard and visualization gallery. |

About InetSoft

InetSoft is a pioneer in delivering easy, agile, and robust business intelligence software that makes it possible for organizations and solution providers of all sizes to deploy or embed full-featured business intelligence solutions. Application highlights include visually-compelling and interactive dashboards that ensure greater end-user adoption plus pixel-perfect report generation, scheduling, and bursting.

InetSoft's patent pending Data Block technology enables productive reuse of queries and a unique capability for end-user defined data mashup. This capability combined with efficient information access enabled by InetSoft's visual analysis technologies allows maximum self-service that benefits the average business user, the IT administrator, and the developer. InetSoft solutions have been deployed at over 5,000 organizations worldwide, including 25% of Fortune 500 companies, spanning all types of industries.

|

Read how InetSoft saves money and resources with deployment flexibility. |

More Articles About Data Issues in the Enterprise

Balancing Control with Self-Service - We can support the IT layer, where they have got tight controls on things, but enable self-service for the users. But I am sure that various vendors are going to come out with their own solutions to the problem as well...

Learning Data Warehouses in BI - It is taking the principles and concepts from learning data warehouses in BI and applying them to the rest of the data systems and the rest of the applications and essentially the rest of the organization. I think the key thing there is to understand what master data is all about...

Loading Data From A Variety Of Sources - The other side of this, there are a bunch of software technologies out there today which are pretty flexible at loading data from a variety of sources. The data mashup approach is a really flexible way where you can go out and load different data sources on demand or on a schedule. You might schedule the refresh of a cache during the morning. It might be 10 in...

MDM Definition - There's a lot of talk about master data management, otherwise known as MDM, these days. But MDM can be defined very differently at different organizations, we've learned. In fact, experts tell us there are three distinct styles of MDM which require different approaches, different tools, and different best practices...

Operational and Analytical MDM Platform - New releases in the technology have advanced it to be a true enabling operational and analytical MDM platform. I think that the state of the technology is there are a lot of vendors in the marketplace who initially went out with an application to try to solve a specific niche problem...

|

Learn about the top 10 features of embedded business intelligence. |

Performance Management People Need A Liaison - When you're implementing a system like this, the people responsible for knowledge management and the people responsible for performance management need a liaison between them because they were established for completely different purposes...

Pioneering Business Intelligence Solution Brand - Are you researching business intelligence solution brands? InetSoft is a pioneer in dashboard reporting technology. InetSoft's solution is true Software-as-a-Service, not a combination of client developer tools and a web-based delivery platform. Get cloud-flexibility for your deployment. Minimize costs with a small-footprint solution. Maximize self-service for all types of users. No dedicated BI developer required. View a demo and try interactive examples...

Ridiculously Ineffective Customer Measures - Number seven, I am still seeing a lot of ridiculously ineffective customer measures. You look at the whole customer section and most scorecards and how do you think most organizations measure customer satisfaction surveys? What's wrong with the survey? It's old. What else do you have besides the customers you already have...

We Measure The Wrong Things - All right, perspective, we measure the wrong things. There's a difference between a conversation on value and a conversation on volume. We are really, really good at counting, aren't we? There's a ton of stuff you can count about with me. So if you were to find yourself in Manhattan, I am up there two weeks a month. You get on an elevator, and there's your hero, whoever...