Download InetSoft's SQL Server Dashboard Software

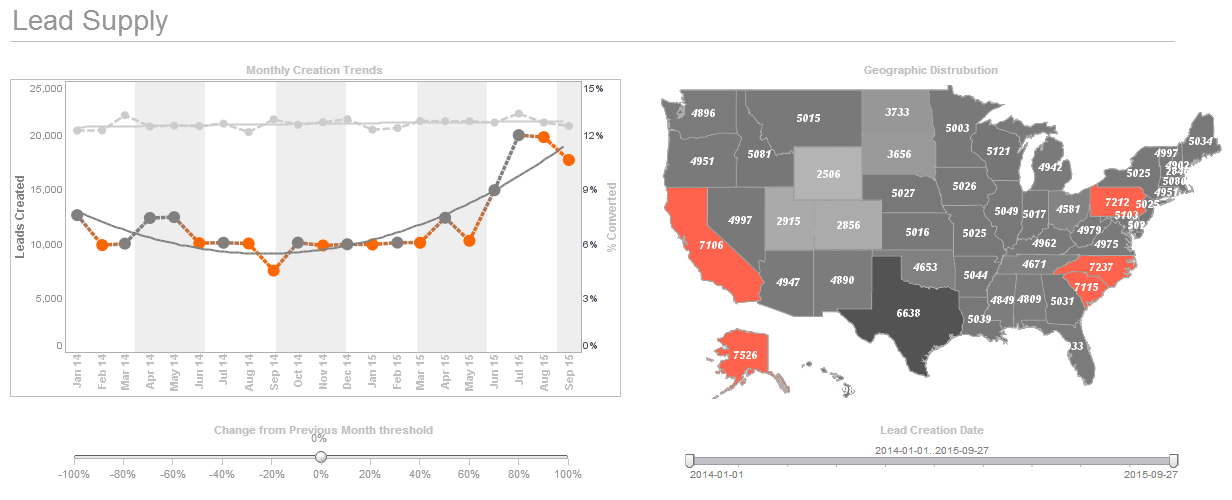

InetSoft offers visualization driven dashboard tools compatible with SQL Server housed data and many other data sources. InetSoft's Web-based dashboard application is 100% Java and enables quick development and easy deployment.

As more businesses look for answers in the cloud and explore database virtualization, the location of data sources may change. However, the need to display data in visually appealing and easy-to-interpret reports will not change. In fact, today's business users and consumers demand highly graphical and interactive views into their data.

InetSoft has been making sophisticated SQL reporting tools for business users since 1996. Product features include:

- Unlimited multi-dimensional charting

- Drag and drop in a web browser

- OLAP data source mashup/visualization

- Transform and manipulate raw data

- Embed business logic with scripting

- Enhance manageability and agility

- Gather up-to-the-minute information

- Reshape reports in real-time

- Minimize performance bottlenecks

About InetSoft

Since 1996 InetSoft has been delivering easy, agile, and robust business intelligence software that makes it possible for organizations and solution providers of all sizes to deploy or embed full-featured business intelligence solutions. Application highlights include visually-compelling and interactive dashboards that ensure greater end-user adoption plus pixel-perfect report generation, scheduling, and bursting. InetSoft's patent pending Data Block™ technology enables productive reuse of queries and a unique capability for end-user defined data mashup.

This capability combined with efficient information access enabled by InetSoft's visual analysis technologies allows maximum self-service that benefits the average business user, the IT administrator, and the developer. InetSoft was rated #1 in Butler Analytics Business Analytics Yearbook, and InetSoft's BI solutions have been deployed at over 5,000 organizations worldwide, including 25% of Fortune 500 companies, spanning all types of industries.

What KPIs and Metrics Are Tracked in Drinking Water Production Dashboards?

Drinking water production is a critical public service that ensures the safety, quality, and availability of potable water for communities. To maintain high standards and efficient operations, water production facilities utilize a variety of Key Performance Indicators (KPIs) and metrics. These KPIs and metrics are essential for performance management, helping to monitor and improve processes, ensure regulatory compliance, and enhance service delivery. Below, we delve into some of the most important KPIs and metrics tracked in drinking water production dashboards, along with their definitions and significance.

1. Water Quality Compliance Rate

Definition: The percentage of water samples that meet the regulatory standards for drinking water quality over a specific period.

Significance: This KPI is crucial for ensuring the safety of the water supply. High compliance rates indicate that the water production process is effectively removing contaminants and maintaining the required quality standards. Non-compliance can lead to health risks and legal penalties.

2. Treatment Efficiency

Definition: The ratio of the volume of treated water to the volume of raw water entering the treatment plant.

Significance: Treatment efficiency reflects the effectiveness of the water treatment processes. High efficiency means that the plant is effectively converting raw water into safe, potable water with minimal waste. It is an indicator of process optimization and resource management.

3. Chemical Usage

Definition: The amount of chemicals used per unit volume of treated water.

Significance: This metric helps in monitoring the operational costs and environmental impact of the treatment process. Efficient chemical usage indicates cost-effective and environmentally friendly operations, while excessive use may point to inefficiencies or problems in the treatment process.

4. Energy Consumption per Unit of Water Produced

Definition: The amount of energy consumed to produce a unit volume of drinking water.

Significance: Energy efficiency is a key performance indicator as it directly impacts the operational costs and environmental footprint of the water treatment facility. Lower energy consumption signifies more efficient operations.

5. Unaccounted-for Water (UFW)

Definition: The percentage of water that is produced but not billed to customers, often due to leaks, theft, or metering inaccuracies.

Significance: High levels of UFW indicate inefficiencies in the distribution system and can lead to significant revenue losses. Reducing UFW is essential for financial sustainability and resource conservation.

6. Customer Complaint Rate

Definition: The number of customer complaints per 1,000 customers over a specific period.

Significance: This KPI measures customer satisfaction and service quality. A high complaint rate may indicate issues with water quality, supply reliability, or customer service, necessitating prompt investigation and resolution.

7. System Reliability

Definition: The percentage of time the water supply system is operational without interruptions over a specific period.

Significance: System reliability is critical for ensuring continuous access to safe drinking water. High reliability rates indicate robust infrastructure and effective maintenance practices.

8. Water Loss Rate

Definition: The percentage of water lost during the distribution process due to leaks, bursts, or unauthorized consumption.

Significance: Water loss management is vital for resource conservation and operational efficiency. High water loss rates require targeted interventions to improve infrastructure and reduce losses.

9. Response Time to Incidents

Definition: The average time taken to respond to and resolve incidents such as leaks, bursts, or water quality issues.

Significance: Quick response times are essential for minimizing service disruptions and maintaining customer trust. Efficient incident management reflects well-organized operational processes.

10. Employee Training Hours

Definition: The total number of training hours provided to employees within a specific period.

Significance: Regular training ensures that staff are up-to-date with the latest technologies, regulations, and best practices. This KPI is an indicator of the organization's commitment to continuous improvement and operational excellence.

11. Maintenance Cost per Unit of Water Produced

Definition: The total maintenance cost divided by the total volume of water produced.

Significance: This metric helps in understanding the cost-efficiency of the maintenance activities. High costs may indicate aging infrastructure or inefficient maintenance practices, while low costs combined with high reliability suggest effective maintenance strategies.

12. Asset Condition Index

Definition: A composite index that reflects the overall condition of the water production and distribution assets.

Significance: A high asset condition index indicates well-maintained and reliable infrastructure, reducing the risk of failures and service disruptions. It aids in planning capital investments and maintenance schedules.

13. Safety Incident Rate

Definition: The number of safety incidents per 1,000 employee hours worked.

Significance: Ensuring a safe working environment is paramount in water production facilities. A low safety incident rate indicates effective safety protocols and a strong safety culture, which are crucial for employee well-being and operational continuity.

14. Residual Chlorine Levels

Definition: The concentration of chlorine remaining in the water after the disinfection process, typically measured at various points in the distribution system.

Significance: Maintaining appropriate residual chlorine levels is essential for ensuring the ongoing disinfection of the water supply and protecting against microbial contamination. This KPI helps in balancing safety with taste and odor considerations.

15. pH Levels

Definition: The measure of the acidity or alkalinity of the water, with a target range typically specified by regulatory standards.

Significance: Proper pH levels are crucial for water quality and the effectiveness of the treatment process. Deviations from the target range can affect the disinfection process and the longevity of the distribution infrastructure.

16. Turbidity

Definition: The measure of the cloudiness or haziness of water, usually caused by suspended solids.

Significance: Turbidity is an important indicator of water quality. High turbidity can interfere with disinfection and may indicate problems in the treatment process or contamination in the distribution system.

17. Total Dissolved Solids (TDS)

Definition: The total concentration of dissolved substances in the water.

Significance: Monitoring TDS levels helps in assessing the overall quality of the water. High TDS levels can affect the taste and safety of the water and may indicate the presence of harmful contaminants.

18. Microbial Contaminant Levels

Definition: The concentration of harmful microorganisms, such as bacteria, viruses, and protozoa, in the water.

Significance: Ensuring low levels of microbial contaminants is essential for protecting public health. This KPI is closely monitored to prevent waterborne diseases and comply with health regulations.

19. Supply Pressure

Definition: The pressure at which water is delivered to the distribution system.

Significance: Maintaining adequate supply pressure is crucial for ensuring reliable service to customers and preventing contamination from backflow. This KPI helps in managing the distribution network effectively.

20. Capital Expenditure (CapEx) per Unit of Water Produced

Definition: The total capital expenditure divided by the total volume of water produced.

Significance: This metric provides insight into the investment required for maintaining and expanding the water production infrastructure. Efficient use of capital resources is essential for long-term sustainability and service improvement.

|

View a 2-minute demonstration of InetSoft's easy, agile, and robust BI software. |

More Articles About SQL Server Dashboards

Infrastructure Optimization KPIs - Infrastructure optimization scorecards typically track a variety of key performance indicators (KPIs) and metrics aimed at assessing the efficiency, effectiveness, and performance of an organization's infrastructure. Some common KPIs and metrics tracked on infrastructure optimization scorecards include: Server Utilization: This metric measures the percentage of server capacity that is being utilized at any given time. It helps organizations ensure that server resources are being used efficiently and can identify opportunities for resource consolidation or reallocation...

Public Works Department Dashboard - A Municipal Public Works Department typically uses a Performance Dashboard Application to enhance efficiency, transparency, and decision-making in the management of various public services and infrastructure. Here's how such a department might utilize a performance dashboard: Real-time Monitoring: Infrastructure Status: The dashboard can provide real-time updates on the condition of roads, bridges, water systems, and other infrastructure, allowing officials to monitor for issues and prioritize maintenance...

Replacing IBM Impromptu Reports - InetSoft has received high ratings from its customers in customer support, product reliability, and return on investment. InetSoft customer references have an aggregate content usefulness score of 4.7 based on 2,266 user ratings...

Share Dashboards With Another Business Unit - Using Joe as an example, who's in one business unit, has completed his task. How do you share his work with another business unit? How do you make that happen in a real life project and make it successful? How do you get that? Now using Sam as the example, he's struggling with the same problems and capabilities, like having a way to search through the repository for information and connecting people's work together. People have to learn to collaborate and coexist with each other and this must be easily adaptable some way...