Download InetSoft's Reporting Application for SQL Server

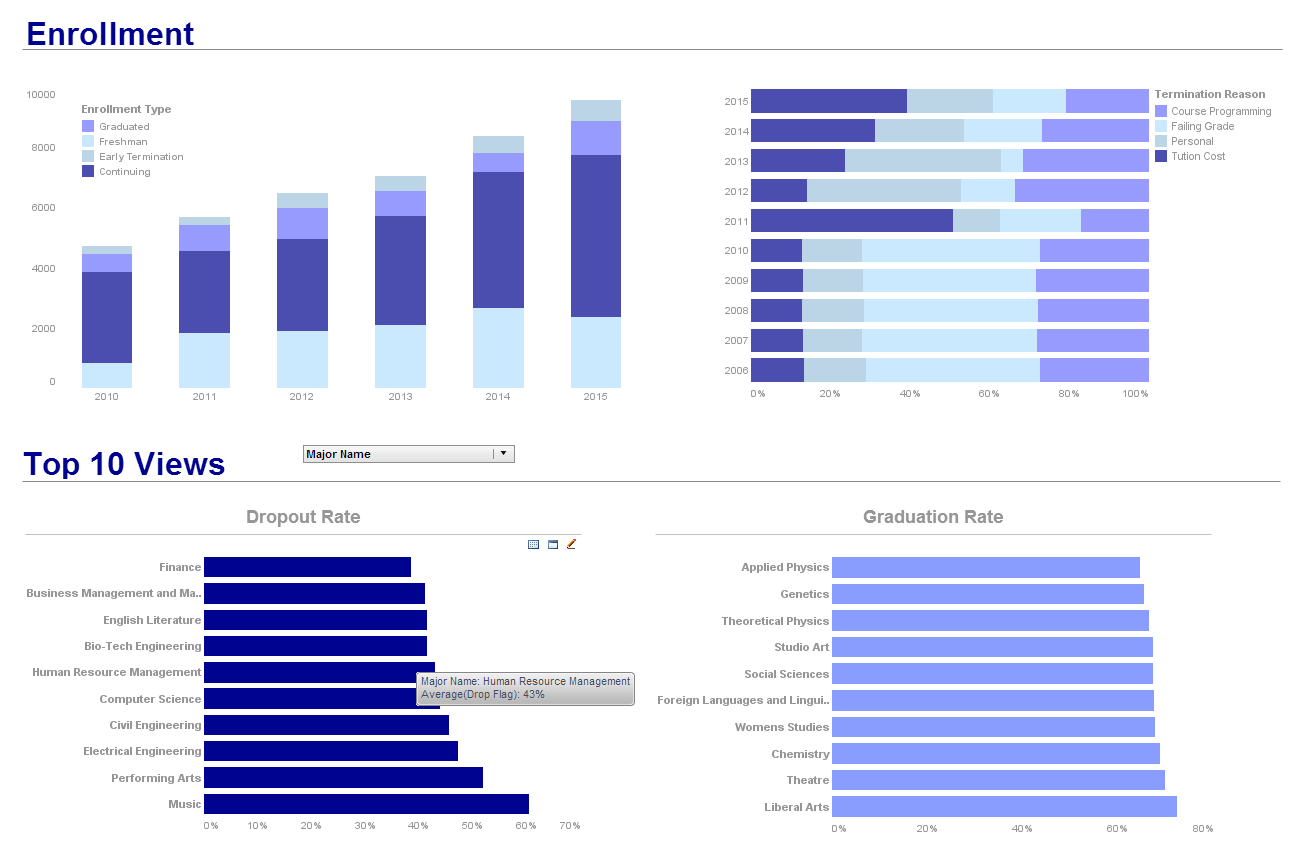

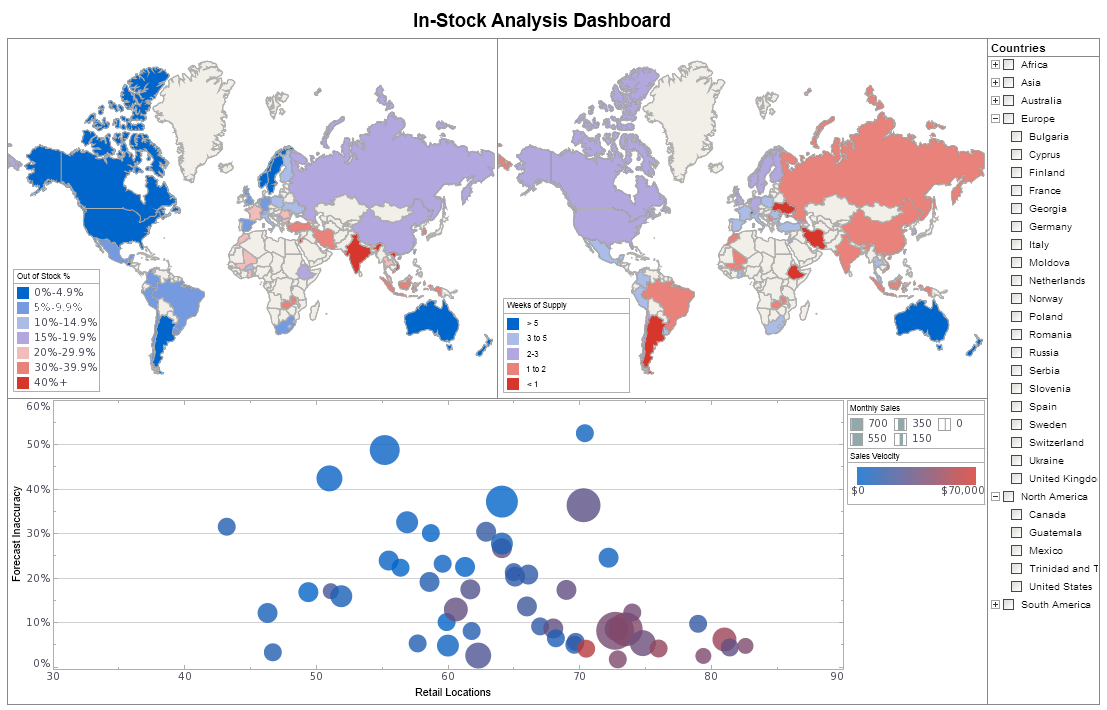

Are you looking to download a reporting application for SQL Server? Since 1996 InetSoft has been making business software that is easy to deploy and easy to use. Build self-service oriented interactive dashboards quickly. View a demo and download one of our applications for free.

Why InetSoft?

InetSoft's mobile BI reporting application is easy enough to be:

- Deployed in just weeks

- Learned by end users with minimal training

- Used by any executive without the aid of IT

agile enough to be:

- Adaptable to changing data and business needs

- Used for data exploration through visualization

- Capable of maximum self-service

and robust enough to:

- Attract the attention of executives

- Meet the demands of power users

- Scale up for organizations of any size

Evaluate StyleBI from InetSoft. It's Easy. Agile. & Robust.

Register for more info and free software software

About InetSoft

Since 1996 InetSoft has been delivering easy, agile, and robust business intelligence software that makes it possible for organizations and solution providers of all sizes to deploy or embed full-featured business intelligence solutions. Application highlights include visually-compelling and interactive dashboards that ensure greater end-user adoption plus pixel-perfect report generation, scheduling, and bursting. InetSoft's patent pending Data Block technology enables productive reuse of queries and a unique capability for end-user defined data mashup.

This capability combined with efficient information access enabled by InetSoft's visual analysis technologies allows maximum self-service that benefits the average business user, the IT administrator, and the developer. InetSoft was rated #1 in Butler Analytics Business Analytics Yearbook, and InetSoft's BI solutions have been deployed at over 5,000 organizations worldwide, including 25% of Fortune 500 companies, spanning all types of industries.

What KPIs and Metrics Are Tracked in Grain Storage and Distribution Dashboards?

In the grain storage and distribution industry, Key Performance Indicators (KPIs) and metrics play a crucial role in ensuring efficiency, quality, and profitability. These dashboards provide real-time insights and help managers make informed decisions. The following are some of the essential KPIs and metrics tracked in grain storage and distribution dashboards, along with their definitions and significance in performance management.

1. Inventory Levels

- Definition: The total amount of grain stored in facilities at any given time.

- Significance: Monitoring inventory levels helps prevent overstocking and understocking, ensuring optimal storage utilization and meeting customer demand without excess holding costs.

2. Storage Capacity Utilization

- Definition: The percentage of total storage capacity currently in use.

- Significance: High utilization rates indicate efficient use of storage facilities, while low rates may suggest underutilization or inefficiencies that could be optimized.

3. Turnover Rate

- Definition: The rate at which stored grain is cycled through the facility, calculated as the ratio of the total volume of grain handled to the average inventory level.

- Significance: A higher turnover rate indicates effective inventory management and quicker movement of goods, which is essential for maintaining freshness and reducing spoilage.

4. Storage Time

- Definition: The average duration that grain remains in storage.

- Significance: Prolonged storage can lead to quality degradation and increased costs. Monitoring storage time ensures timely distribution and minimizes the risk of spoilage.

5. Loss Rate

- Definition: The percentage of grain lost due to spoilage, shrinkage, or pests.

- Significance: A lower loss rate reflects better storage conditions and pest management practices, which are critical for maintaining product quality and profitability.

6. Order Fulfillment Time

- Definition: The time taken from receiving an order to its dispatch.

- Significance: Shorter fulfillment times indicate efficient operations and customer satisfaction, as delays can affect relationships and sales.

7. Transport Efficiency

- Definition: Metrics such as fuel consumption, distance traveled, and delivery times for grain transportation.

- Significance: Efficient transport reduces costs, minimizes environmental impact, and ensures timely delivery to customers.

8. Quality Control Metrics

- Definition: Measures of grain quality such as moisture content, purity, and contamination levels.

- Significance: Maintaining high-quality standards is crucial for customer satisfaction and compliance with industry regulations.

9. Cost per Ton Stored

- Definition: The total cost of storage divided by the amount of grain stored, measured in tons.

- Significance: This metric helps identify cost-saving opportunities and ensures storage operations are financially viable.

10. Warehouse Labor Efficiency

- Definition: Metrics related to labor productivity, such as output per worker or hours worked per ton of grain handled.

- Significance: Efficient labor use reduces operational costs and enhances overall productivity.

11. Order Accuracy Rate

- Definition: The percentage of orders fulfilled without errors.

- Significance: High accuracy rates reduce returns and rework, enhancing customer satisfaction and operational efficiency.

12. Energy Consumption

- Definition: The total amount of energy used in storage and handling facilities.

- Significance: Monitoring energy consumption can identify areas for improvement in energy efficiency, reducing costs and environmental impact.

13. Customer Satisfaction

- Definition: Metrics derived from customer feedback, such as Net Promoter Score (NPS) or customer satisfaction surveys.

- Significance: High levels of customer satisfaction are essential for repeat business and long-term success.

14. Compliance and Safety Metrics

- Definition: Indicators related to regulatory compliance, safety incidents, and adherence to safety protocols.

- Significance: Ensuring compliance and safety minimizes legal risks and protects workers, contributing to a safer and more reliable operation.

15. Yield

- Definition: The percentage of grain recovered from the storage facility compared to the amount initially stored.

- Significance: High yield rates indicate minimal losses and effective storage practices, impacting overall profitability.

16. Downtime

- Definition: The total time when storage or handling equipment is not operational.

- Significance: Minimizing downtime ensures continuous operations and reduces the risk of delays in grain distribution.

17. Forecast Accuracy

- Definition: The accuracy of demand and inventory forecasts compared to actual outcomes.

- Significance: Accurate forecasting helps in planning inventory and reducing costs associated with overproduction or stockouts.

18. Shipping and Receiving Efficiency

- Definition: Metrics related to the speed and accuracy of shipping and receiving processes.

- Significance: Efficient shipping and receiving processes reduce turnaround times and ensure timely availability of grain.

19. Maintenance Costs

- Definition: The total cost incurred for maintaining storage and handling equipment.

- Significance: Monitoring maintenance costs helps in budgeting and can indicate the need for equipment upgrades or replacements.

20. Environmental Impact Metrics

- Definition: Metrics related to emissions, waste management, and sustainability practices.

- Significance: Reducing environmental impact is increasingly important for regulatory compliance and corporate social responsibility.

Significance in Performance Management

Enhancing Operational Efficiency

Tracking these KPIs helps identify inefficiencies in storage and distribution processes. For instance, high storage capacity utilization and low loss rates indicate effective use of resources and good storage practices, while high turnover rates and short order fulfillment times reflect efficient handling and distribution.

Cost Management

Metrics such as cost per ton stored, transport efficiency, and maintenance costs provide insights into operational expenses. By monitoring these KPIs, managers can implement cost-saving measures, such as optimizing inventory levels or improving energy efficiency.

Quality Assurance

Maintaining high-quality standards is critical in the grain industry. Quality control metrics, loss rates, and yield measures ensure that the grain remains in good condition throughout storage and distribution. High order accuracy rates also contribute to customer satisfaction and reduce the costs associated with returns and rework.

Customer Satisfaction

KPIs like order fulfillment time, customer satisfaction, and order accuracy rate directly impact customer experience. Meeting customer expectations through timely and accurate deliveries fosters loyalty and repeat business.

Safety and Compliance

Compliance and safety metrics are vital for minimizing legal risks and protecting workers. Ensuring adherence to safety protocols and regulatory requirements reduces the likelihood of accidents and penalties, contributing to a safer and more reliable operation.

Strategic Planning

Forecast accuracy and environmental impact metrics support long-term strategic planning. Accurate demand forecasts help in inventory planning, while environmental metrics align operations with sustainability goals, enhancing the company's reputation and compliance with regulations.

Continuous Improvement

Regularly monitoring and analyzing these KPIs allows for continuous improvement in grain storage and distribution processes. Identifying trends and patterns helps managers make data-driven decisions to enhance efficiency, reduce costs, and improve overall performance.

More Articles About SQL Server Reporting

Digital Marketing Report Frequencies - The frequency of creating a marketing report largely depends on the business's objectives and the nature of its campaigns: Daily, weekly : best for fast-paced campaigns, allowing for real-time monitoring and swift strategy adjustments. For more extended campaigns, a weekly marketing report can help assess if everything is progressing as intended, allowing teams to spot potential issues and refine the strategy if needed...

Making Significant Improvement in KPIs - But to see such a significant improvement in that KPI by itself has just been amazing for us to see. It's a great deal of improvement in such a short time. We've been talking about working capital for a long time, and we've got dozens of reports that explain working capital and which partners are responsible for which part of it. And I've just been stunned to be sitting in a room with the partner's looking at the numbers and pointing at it, and saying oh, how it can be like that...

Real-Time Monitoring Is Appealing - The high-volume, data intensive industries like financial services, telecommunications, some e-commerce retail companies care about real-time information. In hospitals you're seeing real-time monitoring of newborn babies health to know when a baby is going into distress, and be able to respond very quickly to it. In terms of specific departments, line manufacturing and call centers are two areas where real-time analysis is beneficial...

Tool to Make Waterfall Charts Online for Free - To easily and quickly create Waterfall Charts online for free, create a Free Individual Account on the InetSoft website. You will then be able to upload a spreadsheet data set. Once you have done that, you will be able to proceed past the Visualization Recommender, which can usually get you started creating a dashboard. Since the Recommender does not offer the Waterfall Chart as a suggestion, press the Full Editor button...