Evaluate InetSoft's Software for the Visualization of Data

Are you researching solutions for the visualization of data for your organization's internal use or to embed in a commercial application?

Deploy a small-footprint, easy-to-use web-based visualization application from InetSoft.

As an innovator in reporting software since 1996, InetSoft has pioneered the evolution from static reporting towards interactive visualization of data.

InetSoft's award-winning software has been deployed at thousands of organizations worldwide and integrated into dozens of other application providers' solutions serving vertical and horizontal markets of their own.

Why InetSoft?

InetSoft's mobile BI reporting application is easy enough to be:

- Deployed in just weeks

- Learned by end users with minimal training

- Used by any executive without the aid of IT

agile enough to be:

- Adaptable to changing data and business needs

- Used for data exploration through visualization

- Capable of maximum self-service

and robust enough to:

- Attract the attention of executives

- Meet the demands of power users

- Scale up for organizations of any size

Evaluate StyleBI from InetSoft. It's Easy. Agile. & Robust.

Register for more info and free software software

About InetSoft

Since 1996 InetSoft has been delivering easy, agile, and robust business intelligence software that makes it possible for organizations and solution providers of all sizes to deploy or embed full-featured business intelligence solutions. Application highlights include visually-compelling and interactive dashboards that ensure greater end-user adoption plus pixel-perfect report generation, scheduling, and bursting. InetSoft's patent pending Data Block technology enables productive reuse of queries and a unique capability for end-user defined data mashup.

This capability combined with efficient information access enabled by InetSoft's visual analysis technologies allows maximum self-service that benefits the average business user, the IT administrator, and the developer. InetSoft was rated #1 in Butler Analytics Business Analytics Yearbook, and InetSoft's BI solutions have been deployed at over 5,000 organizations worldwide, including 25% of Fortune 500 companies, spanning all types of industries.

How Do Analysts at an Epitaxy Equipment Manufacturer Use Data Visualization?

Epitaxy equipment is used in the semiconductor industry to grow crystalline layers on a substrate crystal, ensuring that the deposited layer maintains the same crystallographic orientation as the underlying substrate. This precise growth technique is crucial for manufacturing high-performance electronic devices, including integrated circuits (ICs), light-emitting diodes (LEDs), and solar cells.

The epitaxy process involves techniques such as molecular beam epitaxy (MBE) and chemical vapor deposition (CVD). In MBE, beams of atomic or molecular species are directed at the substrate in a high vacuum, allowing for the deposition of ultra-thin layers with atomic precision. CVD involves reacting gaseous precursors at the substrate surface, resulting in the formation of a crystalline layer.

Epitaxy equipment ensures the high purity and structural perfection of the deposited layers, which are essential for the optimal performance of semiconductor devices. These layers can be engineered to have specific electrical, optical, and mechanical properties, enabling the development of advanced technologies like high-speed transistors, efficient LEDs, and high-efficiency solar cells. The precision and control provided by epitaxy equipment are fundamental to the ongoing innovation and miniaturization in the semiconductor industry, driving advancements in electronics and optoelectronics.

Data visualization is an indispensable tool for analysts at an epitaxy equipment manufacturer. It allows them to convert complex data sets into understandable, actionable insights. Epitaxy equipment manufacturing is a highly specialized field that involves sophisticated processes for producing high-quality crystalline layers, essential for semiconductor devices. Here's a detailed look at how analysts in this industry use data visualization to enhance their work across various stages, including research and development, production, quality control, and customer support.

Research and Development (R&D)

Process Optimization

Analysts in R&D use data visualization to optimize epitaxy processes. Visual tools such as heatmaps and contour plots help in understanding the relationship between different process parameters (e.g., temperature, pressure, gas flow rates) and the quality of the crystalline layers. By visualizing this data, analysts can identify optimal settings that produce the best quality layers.

For instance, a heatmap could display the thickness uniformity of a layer as a function of substrate temperature and gas flow rate. By examining this visual representation, analysts can pinpoint the conditions that minimize thickness variations, leading to more consistent and higher-quality products.

Material Properties

Visualizing material properties is crucial for developing new epitaxial materials and structures. Analysts use scatter plots, bar charts, and line graphs to study the properties of materials under different conditions. For example, they might plot the relationship between doping concentration and electrical conductivity to identify the best doping levels for specific applications.

3D surface plots are particularly useful for visualizing the interaction between multiple variables and their impact on material properties. These visualizations enable analysts to explore complex relationships and optimize material compositions more effectively.

Production

Monitoring and Control

In the production phase, data visualization tools are essential for monitoring and controlling the epitaxy process. Real-time dashboards display key performance indicators (KPIs) such as temperature stability, gas flow rates, and layer thickness. These dashboards use color-coding and alert systems to help operators quickly identify and respond to deviations from the desired process parameters.

Control charts and trend graphs are used to monitor process stability over time. By visualizing this data, analysts can detect any drifts or shifts in the process that might indicate equipment wear or the need for maintenance.

Yield Analysis

Yield analysis is a critical aspect of production where analysts use data visualization to track the number of defect-free layers produced. Pareto charts and defect density maps help identify the most common defects and their locations on the wafer. By visualizing this information, analysts can prioritize corrective actions and process improvements to enhance yield.

Histograms and box plots are used to analyze the distribution of layer thicknesses, doping concentrations, and other critical parameters. These visualizations provide insights into the consistency of the production process and help identify areas for improvement.

Quality Control

Defect Inspection

Data visualization is pivotal in the quality control phase, especially for defect inspection. High-resolution imaging techniques, such as scanning electron microscopy (SEM) and atomic force microscopy (AFM), generate detailed images of the crystalline layers. Analysts use visual software to annotate these images, highlighting defects such as dislocations, voids, and contaminants.

False color images and 3D surface plots are used to enhance the visualization of surface topography and defect distribution. These visual tools help analysts quickly assess the quality of the layers and determine if they meet the required specifications.

Statistical Process Control

Statistical process control (SPC) relies heavily on data visualization to ensure the production process remains within defined limits. Control charts, such as X-bar and R charts, display variations in critical parameters over time. By monitoring these charts, analysts can detect trends or patterns that might indicate potential quality issues.

Cumulative sum (CUSUM) charts and exponentially weighted moving average (EWMA) charts are used to detect small shifts in the process. These visualizations provide early warning signals, allowing analysts to take corrective actions before significant quality problems arise.

Customer Support

Performance Reporting

Data visualization is also vital in customer support, where performance reporting is a key activity. Analysts create visual reports that summarize the performance of epitaxy equipment for customers. These reports include graphs and charts that display metrics such as uptime, throughput, and defect rates.

Performance dashboards are shared with customers, providing them with real-time insights into the operation of their equipment. These dashboards use visual indicators to highlight any issues and track the progress of corrective actions.

Predictive Maintenance

Predictive maintenance is another area where data visualization plays a crucial role. Analysts use historical data from equipment sensors to develop predictive models for maintenance scheduling. Time-series plots and correlation matrices help visualize the relationship between different sensor readings and equipment failures.

By visualizing these patterns, analysts can predict when maintenance is likely to be needed and schedule it proactively, reducing downtime and improving equipment reliability.

Collaboration and Decision-Making

Cross-Functional Teams

Data visualization facilitates collaboration and decision-making across cross-functional teams. Engineers, scientists, production managers, and quality control specialists can all benefit from visual representations of data that are easy to interpret and discuss. Visualization tools such as interactive dashboards allow team members to explore data from different perspectives, fostering a collaborative approach to problem-solving.

Executive Reporting

For executive reporting, concise and impactful visualizations are essential. Analysts create executive dashboards that summarize key metrics and trends using high-level visualizations such as KPI gauges, trend lines, and summary tables. These visual tools provide executives with a clear overview of the company's performance and help inform strategic decisions.

Advanced Techniques and Tools

Machine Learning and AI Integration

Advanced data visualization tools are increasingly integrating machine learning (ML) and artificial intelligence (AI) to enhance data analysis. For example, anomaly detection algorithms can be visualized using heatmaps and scatter plots, highlighting unusual patterns that might indicate potential issues in the epitaxy process.

AI-powered predictive analytics can be visualized through predictive trend lines and confidence intervals, providing analysts with a visual representation of future process performance based on historical data.

Augmented and Virtual Reality

Emerging technologies such as augmented reality (AR) and virtual reality (VR) offer new possibilities for data visualization in epitaxy equipment manufacturing. AR and VR can create immersive visualizations of the epitaxy process, allowing analysts to explore data in a 3D environment. This can be particularly useful for visualizing complex spatial relationships and interactions in the crystalline layers.

More Articles About Visualization of Data

Baseball Teams Use Data Visualization - Professional baseball teams utilize data visualization software to analyze and present vast amounts of data in a visually engaging and intuitive manner. Here are several ways in which they leverage data visualization software: Performance Analysis: Teams collect and analyze various performance metrics of players, such as batting average, on-base percentage, slugging percentage, fielding efficiency, pitch velocity, and more. Data visualization software helps them create interactive charts, graphs, and heat maps to identify patterns, trends, and outliers, allowing teams to evaluate individual and team performances effectively...

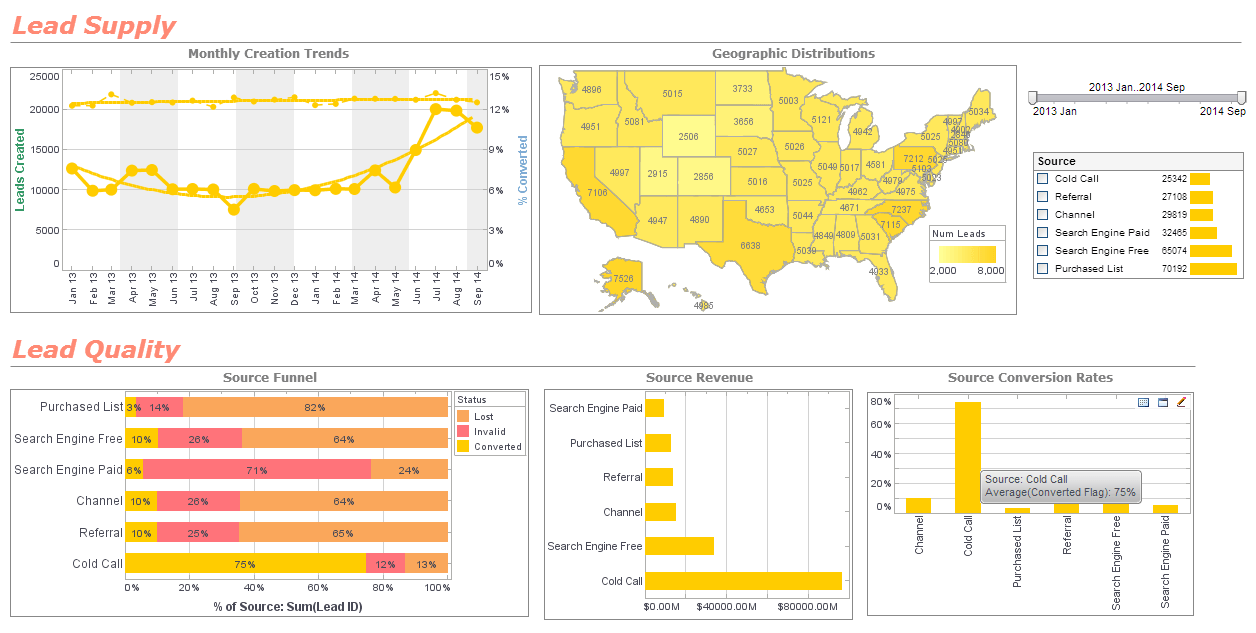

Collection of Good Information Dashboard Examples - Below are some good examples of Information Dashboards. An information dashboard is management tool that allows information, whether it be numerical or text, to be represented in a visual dashboard. Good information dashboards can combine this data into easy to read graphical representations of the business they are analyzing. Information dashboards give management the ability to track and change data when needed in order to make the necessary changes in the workplace...

Length of Stay Metrics - A key performance indicator (KPI) in hospice management dashboards is the number of patient admissions and duration of stay. This measure sheds light on how quickly patients are admitted to hospice care and how long they stay there on average. Administrators can spot trends, evaluate how resources are allocated, and guarantee that patients get the right kind of care the whole time they are there by monitoring these KPIs...

Tool to Make a Box and Whiskers Chart Online for Free - To easily and quickly create Box Plots online for free, create a Free Individual Account on the InetSoft website. You will then be able to upload a spreadsheet data set, as shown below. Once you have done that, you will be able to proceed to the Visualization Recommender, which will get you started creating a dashboard. To start with a Box Plot, select a dimension and measure that you want to use, and press the Box Plot button in the top bar of the Recommender...