What is an Example of Drill-Down in the Customer Relationship Management Scenario?

This is a continuation of a transcript of a Webinar hosted by InetSoft entitled "Designing a Good Dashboard." The speaker is Mark Flaherty, CMO at InetSoft.

Mark Flaherty (MF): A good example is getting business intelligence on individual customers. You can understand their entire purchase behavior history. You can see what they purchase, and this is how drilling down can help close more deals, close them more quickly, generate cross selling opportunities and increase revenues. When you understand that this is what you can do, for the individual sales rep, first you summarize the information so it’s understandable to him or her. Then it should be intuitive where to drill down to help make the specific decision.

What is some advice for designing a data visualization solution?

When you start offering a dashboard initially, you want to create a team that has a lot of expertise. Someone should be very experienced with dashboard intelligence, in the ideal world, in your organization.

You also want to have a business analyst who responsible for collecting the requirements of the key performance indicators. And of course, you want the people who will be using the dashboard. Lastly you are going to have to work with the database team as well to make sure there are actual data behind these KPIs. With regard to the infrastructure, you need an IT team to work with, to make sure that database is ready to go, to establish the networking system, whatever the case may be.

| #1 Ranking: Read how InetSoft was rated #1 for user adoption in G2's user survey-based index | Read More |

And as with any project that cuts across functions in a large enterprise, you probably want project management involved to make sure everybody is communicating properly. Those are the technical aspects you would like to see in a dashboard development team. The first thing you start off with is figuring out the right KPIs, to make sure that the people who will be consuming the dashboards care about them. So generally speaking, you have to go to the stakeholders, ask questions, what are the corporate goals, what you are trying to improve in the organization.

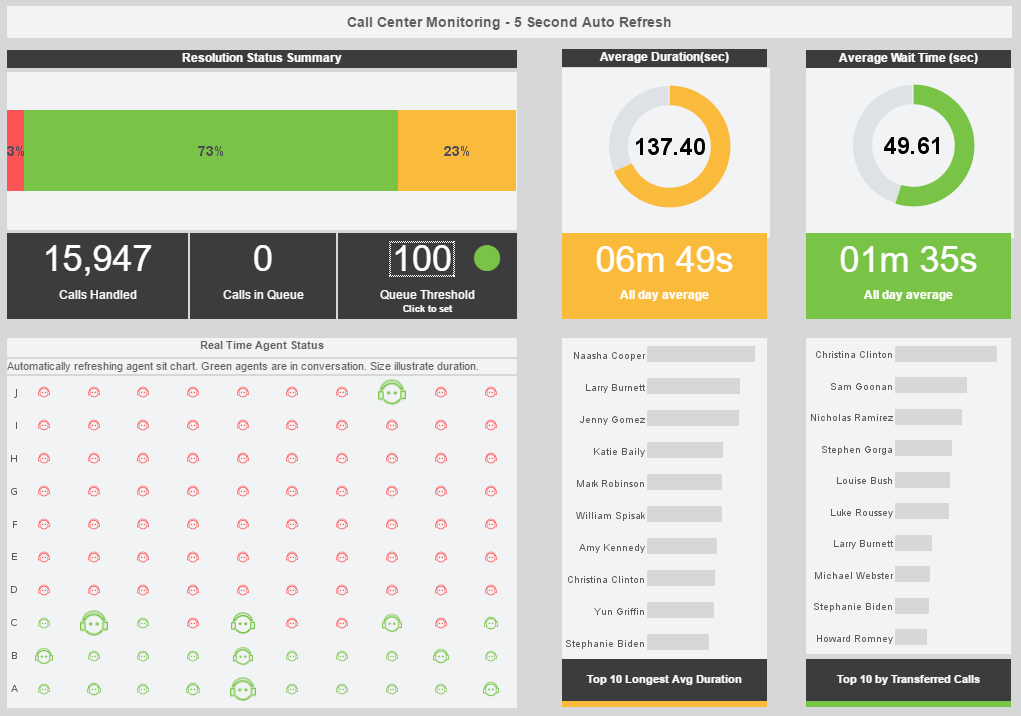

Next come questions about data update frequency. How often will people need to be using this dashboard? Do you use it in real time, or is the data being updated daily in a data warehouse? Finally, are there existing reports in the organization already that could be the basis for arriving at the right KPIs?

How Often Does the Operations Manager of a Maple Syrup Production Company Check His Dashboards?

The frequency with which an operations manager of a maple syrup production company checks their dashboards depends on several factors, including the size of the operation, the complexity of the production process, and the specific metrics being tracked. However, a typical pattern might look like this:

1. Daily Monitoring

- Production Efficiency: During peak sap-harvesting season (spring), the operations manager is likely to check the dashboards daily to monitor the efficiency of sap collection and syrup production. Maple syrup production is highly time-sensitive during this period, and keeping an eye on the volume of sap collected, processing times, and bottling can help prevent production slowdowns.

- Quality Control: Daily tracking of sap quality (sugar content, purity) and syrup grade is crucial to ensure that the end product meets the necessary standards.

2. Weekly Monitoring

- Inventory Levels: The operations manager may check dashboards related to raw material (sap) inventory and finished product levels weekly. This helps with planning for bottling, packaging, and distribution, especially during busy periods when product turnover is high.

- Labor Efficiency: Weekly dashboards might also track labor performance, particularly for bottling and packaging teams, allowing the manager to optimize staffing levels.

3. Monthly/Quarterly Monitoring

- Sales and Distribution: Sales data, customer orders, and distributor performance are typically reviewed monthly or quarterly. This data helps the operations manager align production levels with market demand and distribution requirements.

- Maintenance and Equipment Performance: Key metrics related to equipment health, maintenance schedules, and energy consumption are often monitored on a monthly basis to ensure smooth operations.

4. Seasonal Monitoring

- Yield Comparison and Long-Term Trends: Since maple syrup production is seasonal, the manager may review seasonal production reports and compare them to previous years' yields. These trends help in adjusting future production strategies.

5. Real-Time Monitoring

- Critical Alerts: In case of critical system alerts, like equipment failures or significant deviations in sap quality, the operations manager might receive real-time alerts via dashboards to quickly address issues and avoid disruptions in production.

| Previous: Designing a Good Dashboard |