Are there templates for dashboards for a given industry?

This is a continuation of a transcript of a Webinar hosted by InetSoft in September 2017 entitled "Designing a Good Dashboard." The speaker is Mark Flaherty, CMO at InetSoft.

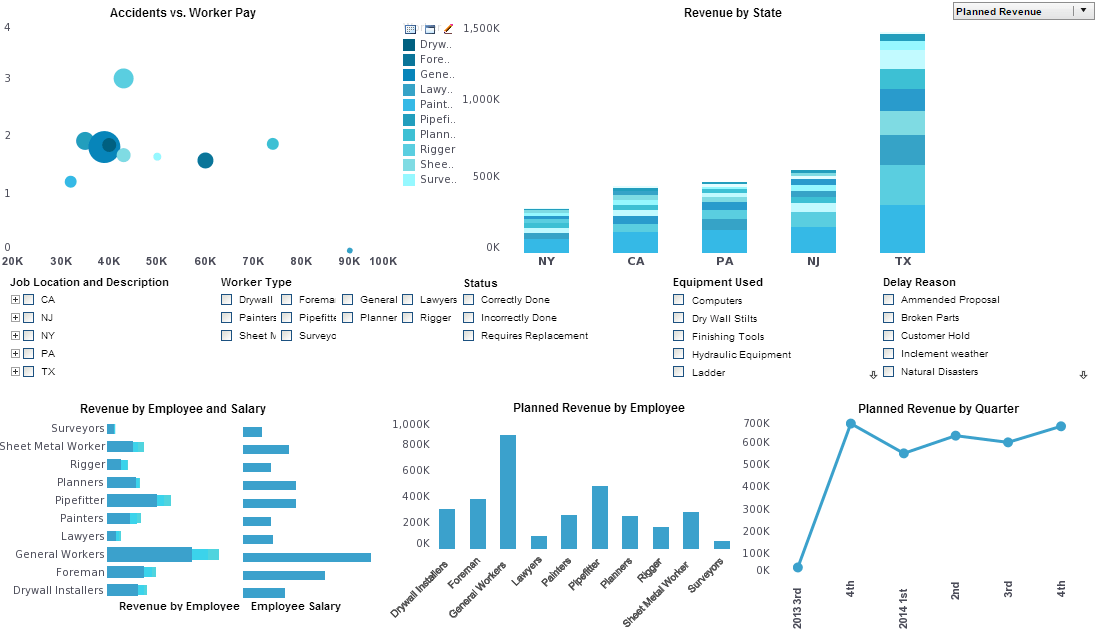

Mark Flaherty (MF): It certainly is a big challenge for a company who doesn’t know what they want in their dashboard to start with a blank piece of paper. So it can be helpful to look at examples of ones that companies in your industry have created. So we try to share examples like that. It makes it easier to adopt. Another point about dashboard templates is that sometimes you want to have fairly rigid templates that people use, where they don’t have the data mashup capability, for instance.

Let’s say you have a few thousand sales people. You want to have the same dashboard for each of them. You have to standardize on certain KPI, so everybody is going to see the same thing, and they can talk the same language. That’s not to say the dashboard is frozen over time. It can be refined, but the changes would be the same for everyone. Another example is in a hospital, where you have many physicians. You don’t want a customized dashboard for each physician. You don’t want them to be playing with their dashboard. It’s the roles like business analysts, CFOs, marketing VPs, or financial analysis who absolutely do not want to live with just a single template, and they need data mashup capabilities.

|

View a 2-minute demonstration of InetSoft's easy, agile, and robust BI software. |

The reason for this rigidity for when we are talking about thousands or ten of thousands of end users is that management wants to align the workforce with the corporate goals. The story we often hear is we’ve been in to umpteen strategy meetings where we talk about our goals and what we are going to be working on. And then 15 minutes after everybody leaves, you forget about what the goals and strategies are. How do we make those more visible? Being able to lock those down KPI dashboards down and standardize them is crucial.

Now it is conceivable to offer both kinds of dashboards, both static and customizable. One set should be standardized so people keep communicating and collaborating on corporate goals. But it’s just human behavior to want to see what I want to see, so just give me that option as well. It’s not one or the other, it can be both. Such as in sales, you have the official sales dashboard. We are going to use it to talk about performance in the sales meeting. But as an individual, may be I just care about two other KPIs in order to get my job done so I can deliver on those standardized KPIs.

|

Read the top 10 reasons for selecting InetSoft as your BI partner. |

Case Study: LipidBioTech's Use of Departmental Dashboards for Enhanced Operations

LipidBioTech Inc. is a leading player in the lipid biotechnology industry, focusing on the development and production of high-quality, bio-based lipids used in various industries, including pharmaceuticals, food production, and cosmetics. LipidBioTech's products include essential fatty acids, emulsifiers, and lipid-based drug delivery systems.

With increasing global demand for sustainable and biocompatible products, the company experienced significant growth. As their operations scaled, they faced challenges related to managing data across multiple departments. They recognized the need for a robust system to track performance, streamline operations, and improve collaboration between key departments like R&D, production, quality control, sales, and finance.

Challenge

As the company expanded, LipidBioTech encountered the following challenges:

-

Fragmented Data Management: Each department operated in silos, using independent tools and spreadsheets to track key performance metrics. This led to disjointed reporting, making it difficult for senior management to get a clear, real-time view of the overall health of the company.

-

Inefficient Decision-Making: The lack of centralized data visibility delayed critical decision-making processes. For example, the R&D team struggled to communicate product development timelines to the production team, which affected product launch schedules.

-

Resource Allocation Issues: Without real-time insights into operational bottlenecks or departmental resource use, the company frequently misallocated resources. Production teams often experienced supply shortages, while other departments had excess.

-

Cross-Departmental Collaboration: The inability to seamlessly share information across departments hindered collaboration, especially between the research and production teams, which needed synchronized data to ensure a smooth transition from development to commercialization.

Solution: Implementing Departmental Dashboards

To address these issues, LipidBioTech decided to implement departmental dashboards powered by advanced data visualization tools. These dashboards would provide real-time access to critical data for each department, while also offering a holistic view of the company's performance to senior management.

Dashboard Features:

- Real-Time Data Access: Dashboards were designed to aggregate data from all departmental systems (ERP, CRM, production monitoring tools, etc.) into one central location, providing a unified and real-time view of operations.

- Customizable Metrics: Each department could customize their dashboard to focus on KPIs most relevant to their specific operations, ensuring that every team had the data they needed to make informed decisions.

- Cross-Departmental Integration: Data from R&D, production, finance, and sales were integrated, facilitating smoother collaboration and clearer communication.

- Automated Reporting: The dashboards provided automated weekly and monthly reports, allowing management to focus on strategy rather than administrative data gathering.

Departmental Dashboard Use Cases

1. Research & Development (R&D) Dashboard

Objective: Track and manage the development of new lipid products, ensuring that projects move from research to production efficiently.

Key Metrics:

- Number of ongoing R&D projects

- Time-to-completion forecasts for each product

- Budget vs. actual spending on research initiatives

- Success rates of lipid formulations in clinical or performance tests

- Feedback loops with production teams to address feasibility issues

Impact:

The R&D team's dashboard improved their project management by providing a clear timeline for each development stage. This transparency enabled the team to better prioritize high-impact projects and allocate resources to the most promising lipid products. The integration of feedback from the production team also reduced delays in scaling up research outputs for mass production.

2. Production and Quality Control Dashboard

Objective: Optimize production processes and ensure the quality of lipid products meets industry standards.

Key Metrics:

- Production volumes vs. targets

- Machine and equipment efficiency (OEE – Overall Equipment Effectiveness)

- Number of quality control issues or recalls

- Batch failure rates and their root causes

- Compliance with industry standards (e.g., ISO, GMP)

Impact:

The production team benefited significantly from the dashboard's real-time data on machine efficiency and product quality. They could now monitor the entire production line, identify bottlenecks, and proactively address equipment maintenance issues before they affected operations. Quality control data, particularly failure rates and compliance, were shared directly with R&D, allowing both teams to work together to address any formulation issues in new lipid products.

3. Sales and Marketing Dashboard

Objective: Monitor sales performance, customer demand, and market trends to inform strategic decisions and identify growth opportunities.

Key Metrics:

- Monthly and quarterly sales numbers by product line

- Customer segmentation and buying trends

- Market share and competitor analysis

- Sales pipeline performance and conversion rates

- Customer satisfaction scores and feedback on product quality

Impact:

The sales team gained a comprehensive view of their performance across different product lines. They could track demand for specific lipid types (e.g., emulsifiers for food vs. pharmaceutical-grade lipids), enabling them to adapt their sales strategies quickly. The ability to see customer feedback directly on the dashboard also helped the team refine their pitches and provide better post-sale support.

4. Finance Dashboard

Objective: Provide financial transparency across departments, ensuring efficient budgeting and resource allocation.

Key Metrics:

- Revenue vs. expenses per quarter

- Budget allocation by department

- Cost per unit of lipid produced

- Profit margins on each product line

- Financial forecasts and variance analysis

Impact:

The finance department's dashboard allowed them to track spending in real-time, making it easier to adjust budgets and control costs. They could quickly identify which departments were overspending and work with department heads to optimize resource use. Moreover, by tracking the cost-per-unit of each lipid product, they helped identify areas for cost-saving measures in production without compromising quality.

5. Human Resources Dashboard

Objective: Monitor staffing levels, employee performance, and workforce productivity to ensure LipidBioTech has the necessary talent to meet growing demands.

Key Metrics:

- Headcount by department

- Employee productivity scores and performance reviews

- Training and development completion rates

- Employee turnover and retention rates

- Open positions and time to hire

Impact:

HR's dashboard helped LipidBioTech ensure they had the right talent in place to support their growing operations. By tracking workforce productivity and turnover rates, they could proactively address any staffing issues that might hinder production or R&D timelines. The ability to monitor the completion of training programs ensured that employees remained compliant with industry standards, particularly in quality control.

Results and Benefits

Since implementing the departmental dashboards, LipidBioTech has experienced significant improvements in operational efficiency and collaboration:

-

Improved Decision-Making: Dashboards provide real-time data visibility, allowing department heads and senior management to make informed decisions faster. The ability to spot trends, bottlenecks, or inefficiencies in real time has optimized the company's overall performance.

-

Enhanced Cross-Departmental Collaboration: By integrating data from different departments, the dashboards helped break down silos. For instance, production teams now have more visibility into R&D timelines, which helps them plan for scaling up production of new lipid products.

-

Cost and Time Savings: Automated reporting has freed up valuable time across departments. Finance and operations teams no longer need to compile reports manually, which has reduced errors and ensured more accurate budget and resource tracking.

-

Better Resource Allocation: With real-time insights into production performance and resource use, the company has optimized the allocation of equipment, materials, and workforce. The production team now operates with greater efficiency, reducing waste and improving overall output.

-

Greater Scalability: As LipidBioTech continues to grow, the dashboards have allowed them to scale operations without sacrificing control over quality or performance. With clear visibility into each department's metrics, the company can anticipate challenges and adjust strategies accordingly.

| Previous: How Companies Are Using Dashboards |