How Interoperable Or How Dynamic Are Dashboards?

This is a continuation of a transcript of a Webinar hosted by InetSoft entitled "Designing a Good Dashboard." The speaker is Mark Flaherty, CMO at InetSoft.

Mark Flaherty (MF): It’s a big trend. A lot of people talk about it. I mean the reality is it’s still difficult to do with the traditional BI tools that have been out there. We see that with a lot of our customers where they are struggling with these old BI tools and accessing the data sources they have. They look for software like ours to solve these problems and really deliver on this self-service BI concept.

The technology is there to make this easier and easier. We were moving to the ability for savvy users to be able to gather information on the fly, to take advantage of apps that have been created for mash ups.

Are there any pitfalls to self-service BI?

Well, yes, it can become overwhelming if not organized properly. We have seen folks overwhelmed by too much data. You may find that you have 2,000 KPIs the company tracks, so you have two thousand different dimensions available in the design tool.

But that’s not what the true spirit of a KPI is. If you look everybody’s role in an organization, I guarantee you that we could get down to a handful that are relevant to each person or role. What are the key performance indicators that really matter to this person to get their job done?

And these KPIs have to be contextual. There has to be a very clear correlation between the number you see on the screen for an indicator and what the norm is, and then the actions to be taken for a given level. But so many people end up with such a huge amount of data that before you know it, there is no information hierarchy any more.

The whole nature of a dashboard is to be productive and to provide some kind of condensed single point of information that can really help steal your attention a little bit as you go through the day. There are educated folks, dedicated folks who need to analyze the data. But for dashboards, the primary goal is to provide the context necessary for the rest of the organization to make decisions. So we are really looking at the dashboards as a simplification of data processing.

Case Study: Optimizing Production and Sales at PureGlow Skin Care Using Dynamic Dashboards

PureGlow Skin Care, founded in 2010, is a high-end manufacturer of natural skin care products, including moisturizers, cleansers, serums, and sunscreens. With a focus on sustainable and cruelty-free formulations, the company has seen significant growth in both retail and online markets. Their products are distributed across North America, Europe, and Asia, with production centralized at a state-of-the-art manufacturing facility in California.

Despite its rapid growth, PureGlow faced challenges in scaling operations to meet increasing demand while maintaining product quality. Additionally, the company's reliance on fragmented data sources made it difficult for management to make informed decisions in real time. To address these issues, PureGlow implemented Dynamic Dashboards that integrated data from multiple departments, including production, sales, inventory, and quality control, allowing for a unified, real-time view of operations.

Problem Statement

PureGlow Skin Care encountered several challenges as it expanded its operations:

- Production Inefficiencies: The manufacturing process involved multiple stages, such as mixing, filling, packaging, and quality checks, which were often prone to delays due to equipment downtime and manual oversight.

- Demand Volatility: Fluctuations in customer demand, especially for seasonal products like sunscreens, made it difficult to manage inventory levels and production schedules effectively.

- Quality Control Issues: The company experienced occasional quality issues, such as ingredient inconsistencies and packaging defects, which impacted product reputation and customer satisfaction.

- Disconnected Data Sources: Departments operated in silos with separate data systems, making it challenging for management to obtain a comprehensive view of operations. Reports were often outdated by the time they reached decision-makers.

- Marketing Campaign Performance Tracking: PureGlow invested heavily in marketing campaigns, but lacked a unified system to track their effectiveness in real time and optimize advertising spend.

These challenges prompted PureGlow to seek a solution that would integrate data from across the company into a centralized platform that was easily accessible and provided actionable insights.

Solution: Dynamic Dashboards

PureGlow partnered with a business intelligence provider to implement Dynamic Dashboards, enabling the company to integrate data from various sources and visualize it in real time. These dashboards provided comprehensive insights into every aspect of the business, from production and inventory to sales and marketing.

The implementation involved the following key components:

-

Real-time Production Monitoring:

- The dashboard displayed real-time data on the production process, including metrics for machine performance, production cycle times, and throughput at each manufacturing stage.

- Managers were able to monitor the efficiency of mixing, filling, and packaging lines, identifying bottlenecks or issues that could cause delays.

- Predictive maintenance alerts were integrated into the dashboard, providing notifications when equipment was showing signs of wear, helping to minimize unplanned downtime.

-

Demand Forecasting and Inventory Management:

- By integrating sales data with historical trends and seasonal patterns, the dashboard provided real-time demand forecasts, helping the company adjust production schedules proactively.

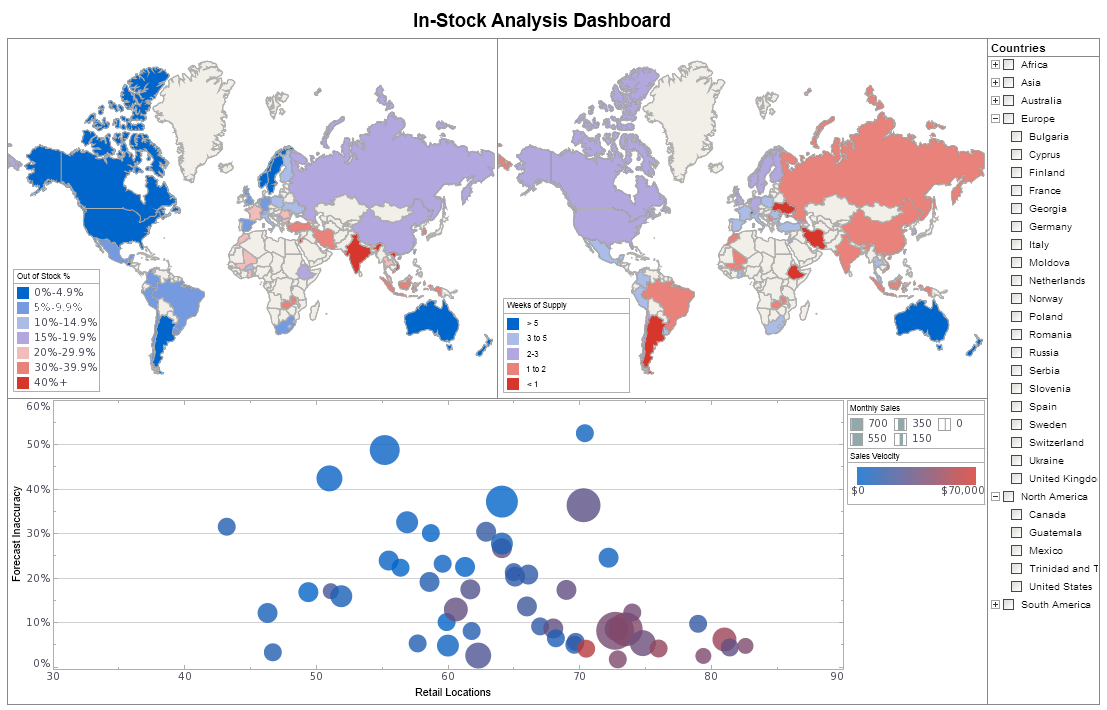

- Inventory levels were monitored dynamically across different distribution centers and retail locations, reducing the risk of stockouts for popular products while avoiding excess inventory buildup.

- The dashboards helped align production with sales promotions and product launches, ensuring sufficient stock was available to meet spikes in demand.

-

Quality Control Tracking:

- Quality inspection data from the manufacturing line was visualized on the dashboard, highlighting trends in product defects, ingredient inconsistencies, or packaging issues.

- The system allowed managers to trace quality issues back to specific batches of raw materials, production lines, or shifts, enabling rapid identification and correction of root causes.

- Interactive dashboards facilitated tracking of supplier performance, comparing the quality of raw materials from different vendors over time, thus improving sourcing decisions.

-

Sales and Marketing Performance:

- The dashboard integrated data from various sales channels, including online stores, retail partners, and direct-to-consumer platforms, providing a unified view of sales performance.

- Marketing campaign data from social media, email, and digital ads were tracked in real-time, allowing the marketing team to measure campaign effectiveness and adjust strategies based on live data.

- The system calculated the return on investment (ROI) for each campaign, enabling PureGlow to optimize marketing spend by focusing on the most effective channels.

-

Supplier and Raw Material Management:

- The dashboard tracked the delivery and quality of raw materials from suppliers, ensuring that production schedules were not delayed due to late or substandard shipments.

- By integrating with supplier data, PureGlow could negotiate better terms with suppliers who consistently met quality standards and delivery timelines, leading to improved cost efficiency.

- Alerts were set up to notify procurement teams when raw material levels fell below a certain threshold, allowing for timely reordering.

Results

The implementation of Dynamic Dashboards led to substantial improvements across PureGlow's operations:

- Increased Production Efficiency: Real-time monitoring and predictive maintenance reduced production downtime by 30%, while optimized production scheduling improved throughput by 20%. This allowed PureGlow to meet increased demand without significant capital investments in new equipment.

- Improved Demand Forecast Accuracy: The integration of sales and historical data improved the accuracy of demand forecasts by 25%, resulting in better inventory management. Stockouts were reduced by 40%, and excess inventory was minimized, leading to a 15% reduction in storage costs.

- Enhanced Quality Control: The use of dynamic dashboards for quality monitoring led to a 20% reduction in defective products. The ability to trace quality issues back to specific batches or suppliers enabled faster resolution, helping maintain PureGlow's reputation for high-quality skin care products.

- Optimized Marketing Campaigns: Real-time tracking of marketing campaigns allowed for agile adjustments, improving the ROI of advertising spend by 30%. The company could shift resources to higher-performing channels quickly, maximizing the impact of each marketing dollar.

- Streamlined Supplier Management: Improved visibility into supplier performance led to better sourcing decisions, resulting in a 10% reduction in raw material costs. Alerts for low inventory levels helped avoid production delays, further boosting production reliability.