What KPIs and Analytics Does a Mining Production Analyst Use?

Effective production management is essential to maximizing output, reducing costs, and ensuring safety in the dynamic and complicated world of mining. Key performance indicators (KPIs) and advanced analytics are used by mining production analysts to evaluate operational efficiency and identify areas for improvement.

The following article will focus on the important KPIs and analytics utilized by production analysts in the mining industry, illuminating their relevance in streamlining mining operations.

| #1 Ranking: Read how InetSoft was rated #1 for user adoption in G2's user survey-based index | Read More |

The Role of a Mining Production Analyst

It's important to understand what a mining production analyst is responsible for before getting into the details. These experts are in charge of compiling, deciphering, and interpreting enormous volumes of data pertaining to mining operations. Their main objective is to support data-driven decision-making and provide insights to improve operational performance, resource allocation, and production processes.

Key Performance Indicators (KPIs) in Mining Production

KPIs are quantitative measurements used to evaluate the effectiveness of different mining operations components. Mining production analysts use a variety of KPIs to gauge operational effectiveness and track progress toward corporate goals. Among the most significant KPIs are:

Production Rate

The production rate is an important KPI that gauges how much ore or mineral is recovered from the mining site during a certain time frame. It gives information on the mining operation's overall productivity and aids in the detection of any possible bottlenecks or inefficiencies.

Overall Equipment Effectiveness (OEE)

OEE is a thorough statistic that assesses the total effectiveness of mining equipment, taking into account elements such as availability, performance, and quality. Analysts might use it to discover underperforming equipment and spend resources to boost production.

Time Utilization

This KPI measures how well the time is put to use for profitable mining operations. When comparing real mining time with downtime for maintenance, repairs, or other non-productive duties, mining production analysts keep track of both.

Cost per Ton of Material Moved

The operational costs related to mining and processing the ore may be better understood by measuring the cost per ton of material transported. Budgeting and cost optimization are aided by it.

Accident and Incident Rate

The significance of safety in mining operations cannot be overstated. The accident and incident rate KPI assists in keeping track of the frequency of safety-related occurrences and acts as a gauge of how well safety procedures are working.

Energy Consumption

Energy is used in substantial quantities during mining activities. Analysts can identify opportunities for the implementation of energy efficiency measures to save costs and the environmental effect by monitoring energy use.

Rock Fragmentation

The effectiveness of subsequent processes, such as crushing and grinding, is directly impacted by rock fragmentation, making it a critical component of mining operations. Increased productivity results from optimizing drilling and blasting procedures by measuring the size distribution of fractured rocks.

Ore Grade

The concentration of precious minerals or metals inside the ore body is referred to as ore grade. Mining production analysts may evaluate the quality of the material being extracted via the analysis of ore grade data, which is important for formulating extraction plans and assessing the mining site's economic sustainability.

|

Read the top 10 reasons for selecting InetSoft as your BI partner. |

Mine Life Index

Based on current production rates and remaining reserves, the mine life index is a KPI that calculates the mine's remaining life. It aids mining corporations in making long-term plans and ensures a seamless transition to new mining operations when older ones near exhaustion.

Waste-to-Ore Ratio

The waste-to-ore ratio compares the quantity of precious ore that is extracted to the amount of rubbish that is eliminated from the mining site. For mining production analysts, lowering the waste-to-ore ratio is a top priority since it has a big influence on profitability and sustainability.

Equipment Downtime

Monitoring equipment downtime enables the detection of serious problems impacting production. Mining production analysts may adopt preventative measures and enhance maintenance procedures to reduce interruptions by assessing the causes of downtime.

Throughput Time

The length of time it takes for material to flow through the whole mining process, from extraction to processing, is known as the throughput time. The volume of material handled in a particular time period rises and operational efficiency is improved by reducing throughput time.

|

Learn about the top 10 features of embedded business intelligence. |

Analytics in Mining Production

Mining production analysts use sophisticated analytics in addition to conventional KPIs to acquire a better understanding of many operational elements. These analytics approaches mine large datasets for useful information using sophisticated algorithms and data processing tools. Among the important analytics techniques used in mining operations are:

Predictive Maintenance

Utilizing data from sensors and other equipment, predictive maintenance foresees machine breakdowns before they happen. Downtime may be reduced and overall equipment performance can be improved by anticipating maintenance requirements.

Spatial Analytics

Spatial analytics enables analysts to analyze geographical data to comprehend the distribution of mineral resources, develop effective extraction routes, and improve logistics for transportation. Mining activities span enormous geographic regions.

|

View live interactive examples in InetSoft's dashboard and visualization gallery. |

Sentiment Analysis

The sentiment of the workforce may be assessed using sentiment analysis, which can be used to a variety of data sources, including employee feedback and social media, to uncover possible issues that can have an influence on output and morale.

Simulation and Modeling

Mining production analysts often recreate mining operations and evaluate different scenarios using simulation and modeling approaches. This helps them to determine the operating techniques that are the most effective and optimize resource allocation.

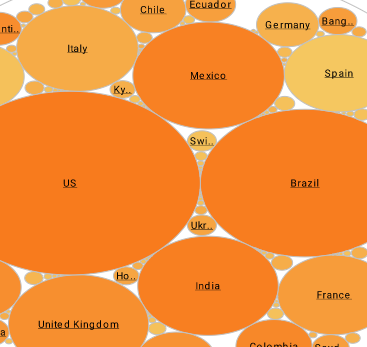

Big Data Analytics

Large volumes of data are produced by the mining sector from a variety of sources. Big data analytics enables analysts to analyze and examine this data to find correlations, patterns, and trends that would not be visible using more conventional approaches.

Predictive Analytics for Ore Grades

To predict the quality of the ore at various mining locations, predictive analytics employs previous data on ore grades, mineralogy, and geology. Mining production analysts can more efficiently manage resources and plan extraction tactics by forecasting ore grades.

|

Learn the advantages of InetSoft's small footprint BI platform. |

Text Analytics for Maintenance Reports

Text analytics is used to extract important data from work orders, maintenance reports, and other text-based data sources. This method aids in identifying recurrent equipment problems, failure trends, and opportunities to enhance maintenance procedures.

Process Mining

In order to understand the real flow of operations in mining processes, process mining entails studying event logs. Process optimization is made possible by the ability of mining production analysts to spot bottlenecks, inefficiencies, and deviations from the norm.

Machine Learning for Equipment Performance

Sensor data from mining equipment may be used to use machine learning algorithms to forecast equipment performance and future faults. Equipment maintenance may be planned proactively by spotting patterns suggestive of equipment failure, minimizing downtime and repair expenses.

Environmental Impact Analysis

To evaluate the effects of mining operations on the environment, mining production analysts also do environmental impact analyses utilizing cutting-edge modeling approaches. This makes it easier to follow environmental laws and put sustainable strategies into effect.