What KPIs and Analytics Are Used on Earthwork Estimating Software Dashboards?

An essential stage of building projects is earthwork estimates, which calls for accuracy and productivity. Earthwork estimate software has become essential to the upheaval in the construction sector brought about by the integration of technology in the digital era.

The dashboard, which displays KPIs and statistics, is a significant aspect of many software systems. This article discusses earthwork estimating software dashboard KPIs and analytics, showing how they help construction professionals make educated choices and maximize project results.

| #1 Ranking: Read how InetSoft was rated #1 for user adoption in G2's user survey-based index | Read More |

Project Progress Metrics

Because earthwork projects must be completed on time, it is essential to track project progress in order to fulfill deadlines and maintain a seamless construction process. The statistics and KPIs listed below are essential for monitoring the progress of a project.

Excavation Volume vs. Target

This statistic contrasts the volume of excavation that actually occurred with the aim that was set. A departure from the anticipated volume may indicate impending delays or inefficiencies, necessitating immediate remedial action.

Completion Percentage

The completion %, which is shown visually on the dashboard, gives a brief summary of how much of the earthwork has been completed in relation to the whole project scope.

Daily Productivity Rates

Monitoring daily output rates facilitates the discovery of patterns and trends. Project managers may evaluate sudden dips in production and take immediate action to remedy problems.

Cost Management Metrics

Effective cost control is essential to building projects that succeed. Dashboards for earthwork estimation tools use analytics and KPIs to closely monitor project costs.

Budget vs. Actual Costs

This comparison offers a current picture of how well the project is staying within the allocated budget. To prevent cost overruns, deviations may be examined and remedial action can be done.

Cost per Cubic Yard

Doing a thorough cost analysis is made possible by figuring out the cost per cubic yard of earth transported. Variations in this measure might draw attention to shifts in the cost of resources or inefficiencies in operations.

Cost Breakdown by Phase

Organizing expenses according to project stages provides detailed information on how the money is spent. This makes it possible to use focused cost-management techniques for certain project components.

|

Learn about the top 10 features of embedded business intelligence. |

Resource Utilization Metrics

Increasing the efficiency of earthwork projects requires optimizing the utilization of resources. The resource use is the focus of the following KPIs and analytics.

Equipment Downtime

It is possible to reduce idle time and increase output by keeping an eye on the downtime of excavation equipment. Strategies for preventative maintenance may be improved by analyzing the causes of downtime.

Fuel Consumption Rates

Fuel consumption measurement offers information on how efficient a piece of machinery is. Unexpected increases might be a sign of problems with operations or that new equipment is needed.

Labor Productivity

An important resource for earthwork operations is labor. Project managers may better allocate resources and spot areas for improvement by tracking worker productivity.

Risk and Safety Metrics

Construction sites must prioritize safety, and earthwork estimating software dashboards use KPIs and analytics to evaluate and reduce risks:

Safety Incidents

A quantitative assessment of project safety may be obtained by keeping track of the quantity and kind of safety occurrences. Effective safety precautions are indicated by a declining trend in occurrences, but an increase may call for a review of safety procedures.

Risk Exposure Index

To offer a general assessment of project risk, this index integrates a number of risk variables. Proactive risk management and the use of preventative measures are made possible by routine monitoring.

Compliance Rates

It is essential to make sure that safety laws and environmental requirements are followed. The dashboard's compliance rates provide users insight into how closely the project adheres to accepted standards.

|

Read the top 10 reasons for selecting InetSoft as your BI partner. |

Environmental Impact Metrics

Environmentally conscious and sustainable methods are prioritized in modern building processes. Dashboards for earthwork estimation software combine analytics and KPIs to track environmental impact.

Erosion and Sediment Control Effectiveness

Reducing the project's environmental impact involves evaluating the efficacy of sediment and erosion control techniques. Variations from anticipated performance may need modifying control schemes.

Material Recycling Rates

Sustainable building techniques are aided by keeping track of the proportion of recycled materials used in excavation operations. It also complies with legal standards and environmentally beneficial project objectives.

Carbon Footprint

Understanding the environmental effect of the project may be gained by calculating the carbon footprint of earthwork operations. This measure is in line with more general sustainability objectives and might influence project certifications.

Quality Control Metrics

For buildings to remain durable throughout time, earthwork quality must be maintained. The following KPIs aid in making sure that the completed job satisfies the required standards of quality.

Compaction Rates

It is ensured that the earth underneath buildings are adequately compacted by measuring the degree of soil compaction. Variations from the ideal compaction rate might be a sign of possible structural integrity problems.

Material Uniformity

Consistent quality is ensured by examining the homogeneity of aggregates and other materials used in earthwork. The manufactured pieces' stability may be impacted by inconsistencies.

Geotechnical Testing Results

Understanding soil qualities is possible via the integration of geotechnical testing findings. This data is essential for planning foundations and comprehending any excavation difficulties.

|

Read how InetSoft saves money and resources with deployment flexibility. |

Communication and Collaboration Metrics

Collaboration and effective communication are essential for project success. Team dynamics and information flow are the main topics of the following KPIs:

RFI (Request for Information) Reaction Times

Evaluating the speed at which RFIs are resolved facilitates the assessment of the project team's communication effectiveness. Response delays might result in bottlenecks in the project.

Change Order Processing Time

Managing change orders effectively is essential for responding to changing project needs. Project budgets and schedules may be impacted by protracted processing periods.

Document Version Control

Maintaining track of project document versions makes ensuring that everyone in the team is working with the most recent and correct data. This aids in preventing mistakes brought on by out-of-date data.

Forecasting and Predictive Analytics

Risk management and proactive decision-making are enhanced by predictive analytics. The KPIs listed below provide perceptions into prospective difficulties and future trends.

Weather Impact Analysis

The dashboard's integration of weather data enables the analysis of potential weather-related effects on project timeframes. This facilitates resource allocation and proactive planning.

Trend Analysis for Resource Demand

Predicting future needs is made easier by recognizing patterns in resource consumption over time. This may help with resource allocation and procurement choices.

Predictive Cost Modeling

Predictive cost modeling projects possible cost changes by using past data and project patterns. This helps with risk reduction and budget planning.

|

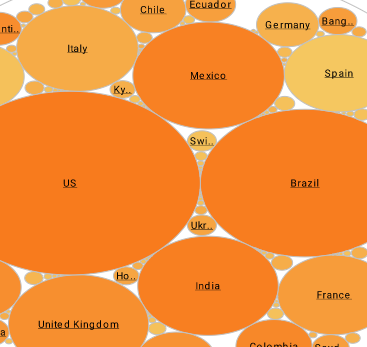

View the gallery of examples of dashboards and visualizations. |

Subcontractor Performance Metrics

Subcontractors are often involved in construction projects. To ensure the success of the project as a whole, subcontractor performance must be monitored:

Subcontractor Productivity Rates

Subcontractors' efficiency may be ascertained by assessing their production. It facilitates the best possible subcontractor selection for upcoming projects.

Compliance with Safety Standards

Ensuring compliance with safety regulations by subcontractors is crucial for the overall safety of a project. Failure to comply may result in dangers and damage the project's reputation.

Payment and Billing Accuracy

It is possible to prevent financial inconsistencies and preserve positive working relationships by keeping track of the correctness of billing and payment procedures with subcontractors.

Real-time Equipment Tracking

To optimize operations and prevent theft or unauthorized usage, real-time monitoring of the location and condition of equipment is essential. This is particularly crucial for large-scale building projects as machinery is essential to the earthwork process.

Equipment Utilization Rates

An examination of the frequency of usage of equipment provides information on its effectiveness. Rental or purchase choices about equipment may be influenced by this information.

Maintenance Schedules

Maintaining adherence to equipment maintenance schedules guarantees optimal equipment performance and helps avert malfunctions.

Fuel Efficiency

In addition to helping with cost control, measuring fuel economy also shows how machine operations affect the environment.