What KPIs and Analytics Are Utilized by Industrial Hygienists?

Industrial hygienists are essential to maintaining the health and safety of employees across a range of sectors. They are in charge of locating and eliminating dangers at work, which may seriously affect the well-being and output of employees.

Industrial hygienists use KPIs and analytics to evaluate, analyze, and improve occupational health and safety. The key KPIs and data that indus trial hygienists use to try to make workplaces safer will be discussed in this article.

| #1 Ranking: Read how InetSoft was rated #1 for user adoption in G2's user survey-based index | Read More |

Exposure Monitoring

An essential component of industrial hygiene is exposure monitoring, which entails calculating the concentrations of potentially harmful materials or agents in the working environment. When evaluating worker exposure to different chemicals, gases, particles, and other potentially hazardous contaminants, this KPI is crucial. To gather information on exposure levels, industrial hygienists use a variety of tools, including dust monitors, gas detectors, and air samplers. When examining this data over time to find patterns, hotspots, and other risk factors, analytics are useful.

Occupational Health Surveys

Through questionnaires, interviews, and medical exams, information on the health and well-being of employees is gathered for occupational health surveys. Industrial hygienists may better understand the frequency of work-related diseases, injuries, and other health issues among workers by using these questionnaires. Understanding the general health of the workforce and assisting in the prioritization of treatments and preventative actions are two benefits of analyzing the survey data.

Hazard Assessment

The process of detecting and assessing possible workplace dangers, which might include chemical exposures, ergonomic risks, and physical hazards, is known as hazard assessment. To determine the degree of risk connected to each danger, industrial hygienists use a variety of instruments and techniques, including risk assessments, safety audits, and hazard identification checklists. Analytics are used to rank risks according to likelihood and severity, which helps firms allocate resources for risk reduction in an efficient manner.

Noise Level Monitoring

Overly loud environments may be harmful to employees' hearing and general health. Noise level monitoring is a KPI that industrial hygienists use to measure and evaluate workplace noise levels. This entails collecting noise data over time using dosimeters and sound level meters. Analytics assist in analyzing the data to identify locations where hearing protection is required and to assess whether noise levels above allowable exposure limits.

Ventilation and Air Quality

In order to keep a workplace healthy, adequate ventilation and air quality are essential. KPIs pertaining to air quality, such as temperature, humidity, and the amount of airborne pollutants present, are monitored by industrial hygienists. Analytics may be used to spot patterns in indoor air quality, ensuring that ventilation systems are operating at peak efficiency and that employees aren't in danger of exposure to dangerous materials.

Respiratory Protection Programs

Industrial hygienists create and oversee respiratory protection strategies in businesses where workers are exposed to respiratory risks. This involves making sure that personnel are properly instructed in the use of respirators, fitting testing respirators, and conducting routine equipment inspections. Analytics may be used to quantify the success of respiratory protection measures, keep an eye on respirator availability, and check compliance with these programs.

|

Learn about the top 10 features of embedded business intelligence. |

Injury and Illness Rates

For industrial hygienists, monitoring injury and sickness rates is an essential KPI. These percentages provide light on how well safety initiatives and preventative actions work. Industrial hygienists may minimize workplace accidents and health concerns by identifying common causes, high-risk behaviors, and patterns that call for focused interventions via the analysis of injury and sickness data.

Training and Education

Preventing workplace mishaps requires making sure that employees are taught in safety procedures and have access to relevant information. By analyzing key performance indicators (KPIs) pertaining to participation, attendance, and knowledge of safety training, industrial hygienists may evaluate the efficacy of their programs. Analytics may be used to find areas where more education is required and training shortages.

Ergonomic Assessments

Optimizing the workplace to lower the risk of musculoskeletal disorders and other ergonomic-related injuries is the main goal of ergonomic evaluations. Industrial hygienists monitor a workplace's ergonomic conditions using key performance indicators (KPIs) such worker discomfort surveys, ergonomic risk assessments, and injury rates. Analytics are useful for pinpointing issues and evaluating how ergonomic upgrades affect productivity and worker well-being.

|

Learn the advantages of InetSoft's small footprint BI platform. |

Compliance with Regulatory Standards

It is the responsibility of industrial hygienists to make sure that workplaces adhere to relevant occupational health and safety laws. They monitor and assess adherence to these standards—which include wearing personal protective equipment, adhering to exposure limits, and maintaining safety equipment—using analytics. Not only may noncompliance result in legal problems, but it also poses a risk to worker safety.

Hazard Communication Programs

Workers must be informed about possible dangers and appropriate safety actions via effective hazard communication. KPIs used by industrial hygienists include employee comprehension of hazard communication programs, safety data sheet compliance, and the accessibility and clarity of danger labels. Analytics aid in evaluating how well these initiatives are doing their job of making sure employees are aware of the dangers involved in their jobs.

Cost Analysis

Cost concerns are a factor in industrial hygiene, even if worker safety and health are its main emphasis. Industrial hygienists may assess the financial effects of safety measures, such as the price of putting control measures in place, training programs, and medical costs associated with occupational diseases and accidents, by using cost-related KPIs and analytics. Organizations using this data may make well-informed choices on the distribution of resources for activities related to occupational health and safety.

|

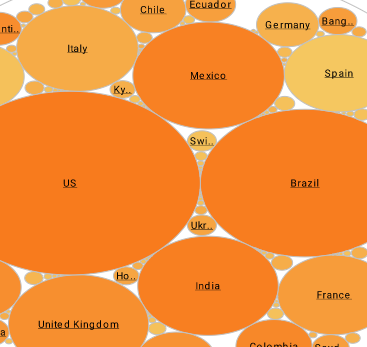

View the gallery of examples of dashboards and visualizations. |

Incident Investigation and Root Cause Analysis

Industrial hygienists look at workplace occurrences in detail to identify the underlying reasons. In this case, key performance indicators (KPIs) include the duration of investigations, the precision of incident reports, and the efficacy of remedial measures. In order to avoid such accidents in the future, analytics are utilized to discover recurrent trends and systemic concerns. This enables targeted actions.

Emergency Preparedness and Response

Industrial hygienists use the following criteria to determine how prepared an area is for emergencies: reaction times, emergency equipment availability, and evacuation plan efficacy. Worker preparedness for crises is enhanced through KPIs linked to response training, emergency drills, and event simulation exercises. Analytics help find places where emergency response strategies need to be refined and enhanced.

Continuous Improvement

Encouraging continual safety and health improvements at work is the aim of industrial hygiene. Industrial hygienists utilize key performance indicators (KPIs) pertaining to employee feedback, safety culture, and the application of incident investigation recommendations to gauge success. In order to evaluate the effectiveness of safety programs and analyze long-term trends, analytics are essential. This helps businesses make data-driven choices that lead to continuous improvement.

|

Learn how InetSoft's data intelligence technology is central to delivering efficient business intelligence. |

Chemical Hazard Assessments

Industrial hygienists often work with dangerous substances. KPIs are used to monitor chemical concentrations, track compliance with permissible exposure limits (PELs), and measure exposure times in order to evaluate chemical exposures. Analytical tools aid in the identification of patterns and anomalies in data related to chemical exposure, hence facilitating the assessment of the efficacy of control measures and the need of modifying chemical handling protocols.

Indoor Air Quality (IAQ) Complaints

Concerns about indoor air quality raised by employees may be signs of impending problems. To pinpoint areas of concern, industrial hygienists monitor key performance indicators (KPIs) linked to IAQ concerns, such as the kind and volume of complaints. By assisting in the investigation of the underlying reasons of complaints, analytics enable businesses implement remedial measures to enhance employee comfort and indoor air quality.

Heat Stress Monitoring

Industrial hygienists in sites where heat-related disorders are an issue utilize KPIs to track the amount of heat stress. This might include taking measurements of the temperature and humidity, monitoring the heat index, and determining the signs of heat stress in workers. Analytics can pinpoint high-risk times and places, making it possible to put preventative measures against heat stress into practice, such more breaks and better hydration habits.

|

View the gallery of examples of dashboards and visualizations. |

Hazardous Waste Management

In order to preserve environmental compliance and a healthy working environment, hazardous waste must be disposed of properly. KPIs are used by industrial hygienists to monitor the production, processing, and elimination of hazardous waste products. Analytics may be used to evaluate the overall efficacy of hazardous waste management systems, find potential for waste reduction, and guarantee correct labeling and containment.

Safety Culture Surveys

One essential element of workplace safety is safety culture. Industrial hygienists use safety culture surveys to find out how workers feel about reporting events, how they see safety, and how committed the company is to safety. KPIs pertaining to survey outcomes and response rates may be used to evaluate the organization's safety culture. Analytics make it possible to pinpoint areas where safety culture needs to be reinforced, which enhances employee engagement and safety results.