Business Intelligence for SAP Netweaver

Are you looking for better business intelligence and visualization tools for your SAP Netweaver data?

InetSoft's software allows for quick creation of visual analyses and BI dashboards. InetSoft's Style Intelligence is a small-footprint Web-based application that connects to your data warehouse as well as almost any other data source and is designed to deliver maximum self-service for BI reporting.

A More Flexible, Easier-to-use Option

Of course, SAP offers dashboarding and visualization software, but if you are interested in an economically more attractive option that is also easier to deploy and use, then consider InetSoft's StyleBI.

As a Web-based server application, no client software is needed, even when creating rich, interactive visualizations. Users can consume dashboards and visual analyses on any PC, Mac, as well as mobile devices such as iPhones, iPads, Android-based tablets and smartphones.

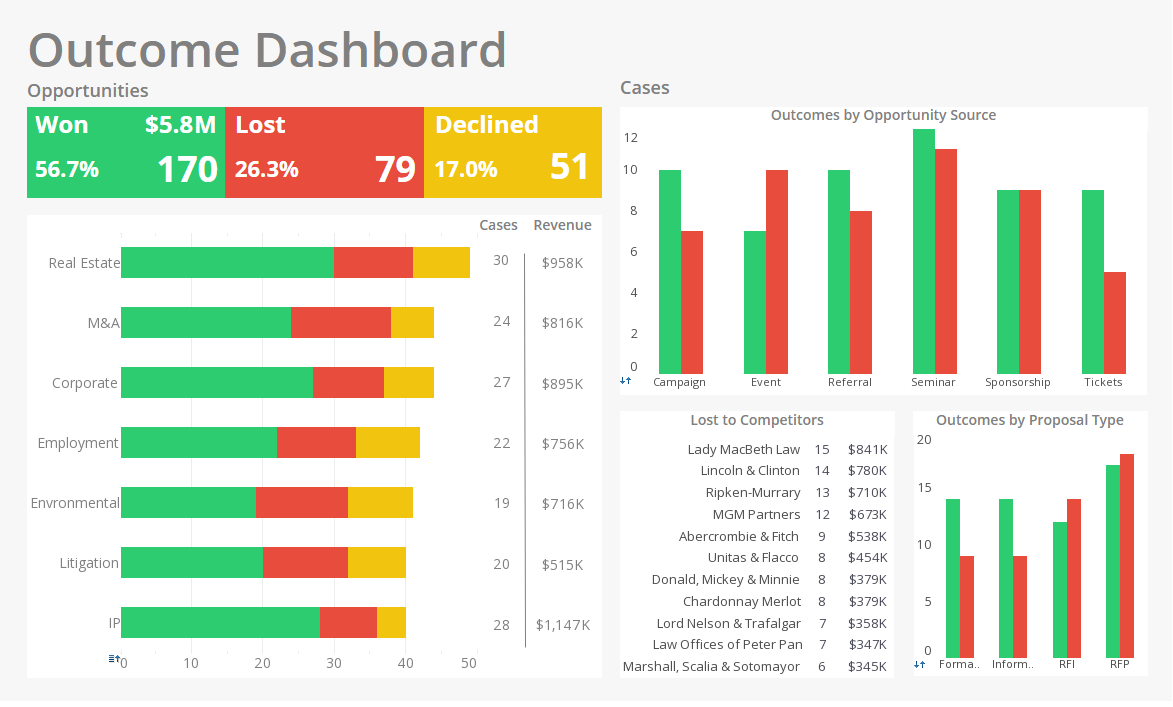

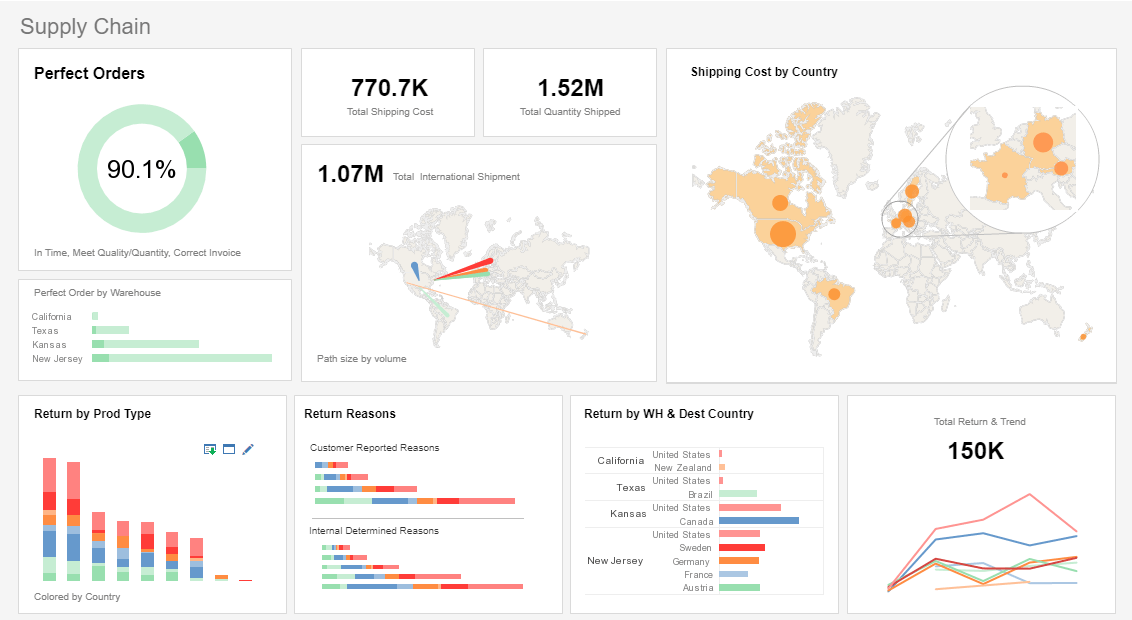

This is an example of a visual analysis that can be built in under an hour.

More BI Features

- Unlimited multi-dimensional charting

- Brushing for data exploration

- Wide range of sophisticated chart types including custom geographic mapping

- Drag and drop design using only a Web browser

- Visualization view re-use and collaboration

- Drilldown across views and into details

- Analytic and monitoring oriented dashboards

- Target-based balanced scorecards

- Alerts for exceptions or business-rule triggers

- Easy Machine Learning

Why an Industrial Noise Control Engineering Firm Chose StyleBI for NetWeaver and Multi-Source Analytics

Industrial Noise Control Engineering is a highly technical, compliance-driven, and project-centric business. Firms in this niche blend acoustical science, materials engineering, and heavy-equipment integration to design silencers, acoustic enclosures, vibration isolation systems, and turnkey mitigation projects for factories, power plants, and ports. Their data lives in many places: SAP NetWeaver and ECC systems for finance and procurement, project management tools for timelines and subcontracts, MES and CMMS for installation and maintenance, and a fast-growing set of IoT and acoustic sensor streams for real-time SPL (sound pressure level) monitoring. Choosing StyleBI as the analytics platform to unify all that information is more than a UI choice — it’s a strategic decision about how the firm will scale, sell, and guarantee compliant outcomes.

At the center of the selection is integration capability. NetWeaver holds canonical ERP records — POs, supplier lead times, cost breakdowns, and invoice histories — and any analytics stack that ignores it will miss cash flow and margin realities. StyleBI’s ability to model data from SQL views, SAP extract layers, and flat feeds lets the firm create a governed semantic layer that combines ERP facts with sensor telemetry and project schedules. That means a project manager can see a live cost-to-complete figure alongside acoustic test results from the field without asking IT to run a new extract. In practice, this cuts reconciliation time and prevents surprises during handovers to operations.

Operationally, the biggest advantage comes from bringing acoustic sensor streams into the same analytical fabric as business records. Noise mitigation projects rely on proof: incoming baseline readings, as-designed noise estimates, and post-installation validation. By ingesting IoT feeds and test measurements into StyleBI, the firm can build dashboards that visualize time-series SPL data, overlay contractually required thresholds, and annotate events like mitigation activation or peak loads. This single pane gives engineers and clients a shared truth — reducing arguments about acceptance tests and accelerating final approval and payment.

Project profit visibility is another high-value outcome. Traditional reporting in SAP often shows only aggregated costs after the fact; it doesn’t expose emerging overruns driven by subcontractor delays, rework, or expedited shipping of isolators. With StyleBI, finance and delivery leads can create profitability views by project phase and component type (e.g., silencers vs. enclosures). Combining NetWeaver cost postings with time sheets and supplier ETA feeds surfaces margin leakage early, letting the firm negotiate change orders or reallocate resources before the client notices. Frankly, that capability often pays for the new platform within the first few major projects.

Regulatory compliance is non-negotiable in noise control. Permits, local noise ordinances, and occupational limits create quantifiable pass/fail criteria for many jobs. StyleBI lets the firm codify compliance rules in the semantic layer and apply them consistently across all dashboards and alerts. Want a daily compliance score for each site, or a list of installations where the measured dB(A) exceeds permit bands during night hours? That’s a simple query away. Having a governed definition of “compliant” also protects the firm legally and builds trust with clients and regulators.

From a UX standpoint, StyleBI’s widget library and embeddability matter. Sales engineers need quick configurators that estimate lead times and costs for alternate attenuation options. Field technicians need mobile ADA-friendly dashboards that show current SPL, equipment status, and a checklist for acceptance tests. Executives want one-click board packs summarizing backlog, win rate on proposals requiring custom attenuators, and cash conversion. StyleBI supports role-specific views delivered through portals or embedded into the company’s project management app — which reduces context switching and the inevitable spreadsheet proliferation that kills report accuracy.

Data governance and security are crucial when you’re dealing with sensitive bids, customer-specific pricing, and legally binding compliance results. Integrating StyleBI with the firm’s SSO and role-based security lets IT expose subsets of the semantic model safely. For example, a subcontractor sees only non-confidential schedule slots and work orders; the finance team sees sensitive costing. NetWeaver remains the source of truth for master data, while StyleBI enforces which KPIs and datasets are visible to which users — a pattern that reduces risk while enabling broad adoption.

Practically speaking, the migration project should be phased. Start by templating the highest-value dashboards: project P&L with rolling variance to estimate, a live site compliance monitor, and a supplier lead-time heatmap tied to critical path components. Run those in parallel with existing reports to validate data quality. Early wins are the lifeblood of change management in engineering teams — show the foreman how a real-time SPL spike correlates with a failed baffle weld and watch adoption accelerate. Training must be hands-on and scenario-driven, not lecture-driven: engineers want to see how the tool helps fix the next incident, not learn abstract features.

Advanced capabilities unlock over time. Once the semantic model is stable, layer in predictive analytics: forecast which sites are likely to breach permit thresholds given upcoming weather and load projections, predict supplier lead-time variability, or estimate probability of rework based on historical defect patterns by fabrication vendor. These are not magic; they are disciplined application of historical data and domain features. StyleBI can host these predictive outputs alongside operational dashboards so planners act before problems crystallize.

Finally, the business case is straightforward but must be articulated in the firm’s language: fewer disputed validations (faster cash collections), lower expedite costs (better margin), reduced time to quote (more bids per AE), and reduced risk of regulatory fines. My opinion: for Industrial Noise Control Engineering firms, analytics that combine NetWeaver’s financial fidelity with real-time acoustic evidence and project telemetry are not a luxury — they are a competitive differentiator. StyleBI’s ability to model, govern, and present those multi-source truths makes it an excellent fit for firms that sell technical assurance and guaranteed outcomes rather than just products.